Emerald F260 – A 4-Axis Aluminum Profile Machining Center.

Designed for high-precision milling, drilling, tapping, and grooving of aluminum and light alloy profiles, the Emerald F260 features a robust gantry structure, advanced automation, and seamless software integration.

| Machining Specifications | Parameter Value |

|---|---|

| Processing Length/Traverse path X-axis | 7,000/9,000/12,000 mm |

| Travel Workpiece Dimensions for Top Surface Machining | W×H = 600 × 260 mm |

| Workpiece Dimensions for Three-Sided Machining | W×H = 400 × 260 mm |

| A-Axis Rotation Range | ±90° |

| Machining Precision | Parameter Value |

|---|---|

| Positioning Accuracy | ± 0.03 mm |

| Positioning accuracy X-/Y-/Z- axis | ± 0.1 mm |

| Positioning accuracy A-axis | ± 0.1° |

| Technical Parameters | Parameter Value |

|---|---|

| Tool Magazine | 9 |

| Clamp | 8 |

| Spindle/Tool Holder Specification | ISO30 S1=7.5KW, S6=9.5KW, 24000rpm |

| Saw Blade Diameter | Ф 80 ~ Ф 150 mm |

| X-Axis Travel Speed | 0~60 m/min |

| Y Z-Axis Travel Speed | 0~30 m/min |

| General Parameters | Parameter Value |

|---|---|

| Machine size (L×W×H) | 9000×2350×2900 mm |

| Machine weight | 4,300 KG |

| Air pressure | 0.5-0.8 MPa |

| Power supply | 400V 50HZ 15KW |

| Air consumption per minute approx | 200 L with spraying |

Designed for high-precision milling, drilling, tapping, and grooving of aluminum and light alloy profiles, the Emerald F260 features a robust gantry structure, advanced automation, and seamless software integration.

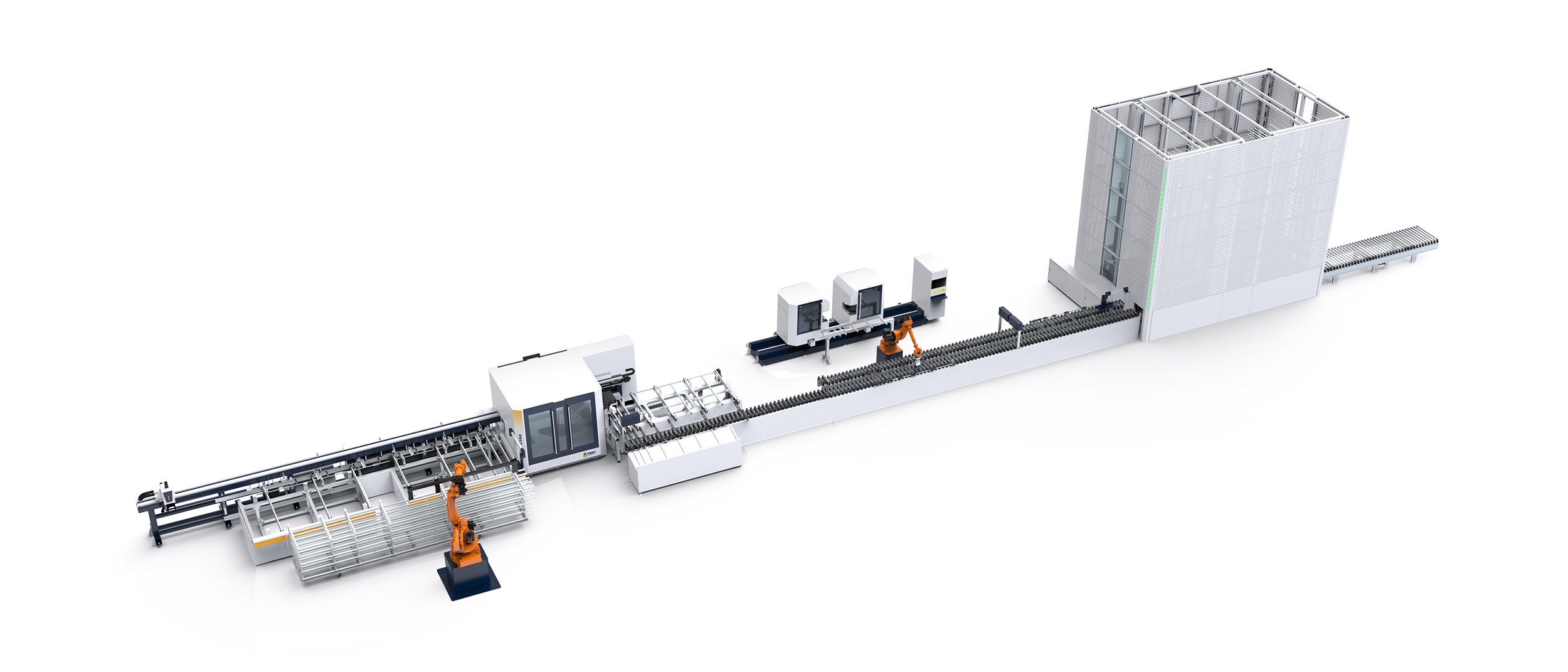

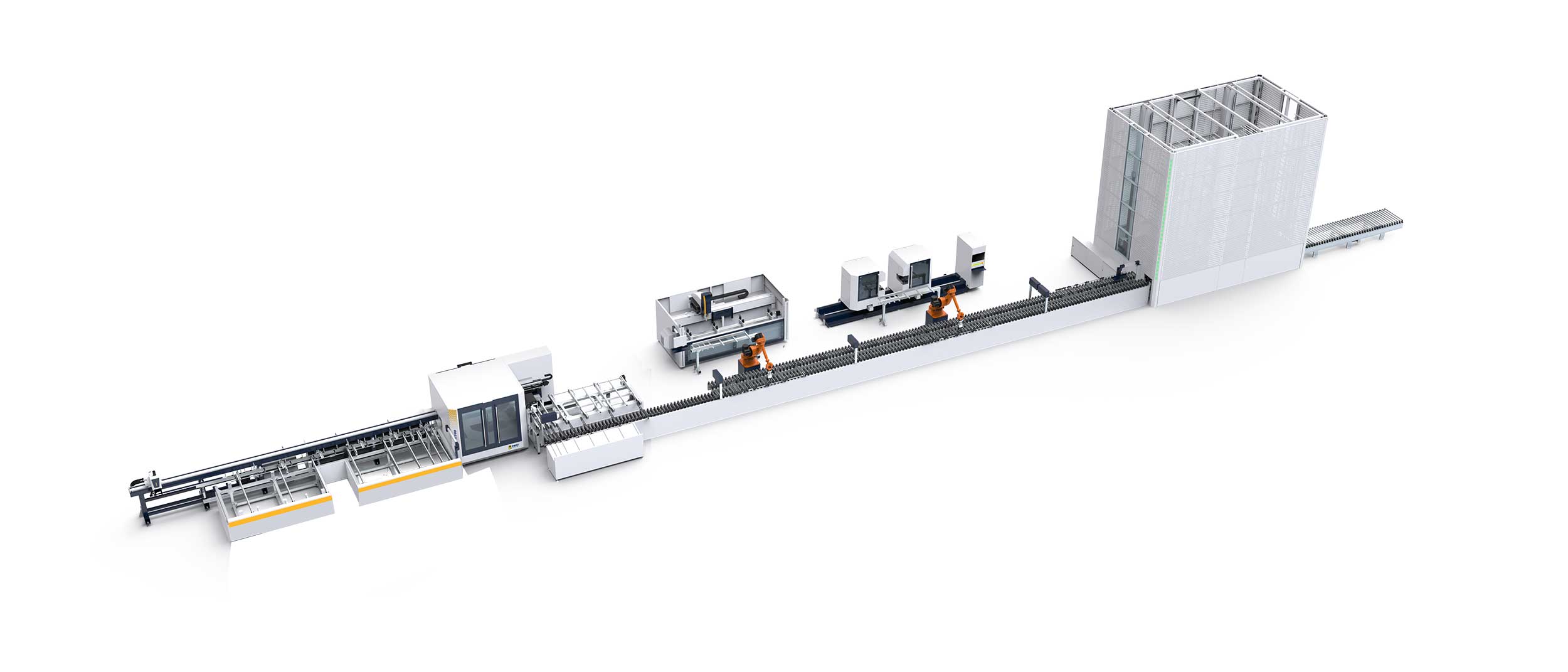

Designed to perform drilling, milling, sawing, and end milling operations for aluminum profiles, the S100 series streamlines production, boosts capacity, and minimizes labor costs through full automation.

Designed for milling, drilling, cutting, and laser machining operations on aluminum and light alloy profiles, the UX260-E combines advanced automation, precision, and efficiency for modern manufacturing needs.

The S200 series ensures detailed material flow organization, strict quality control, and reduced labor and management costs. Each profile is labeled with a sticker containing specifications and a QR code for traceability.

Designed for Milling, Drilling, Cutting, and Laser Machining operations on the heads and ends of aluminum and light alloy profiles.