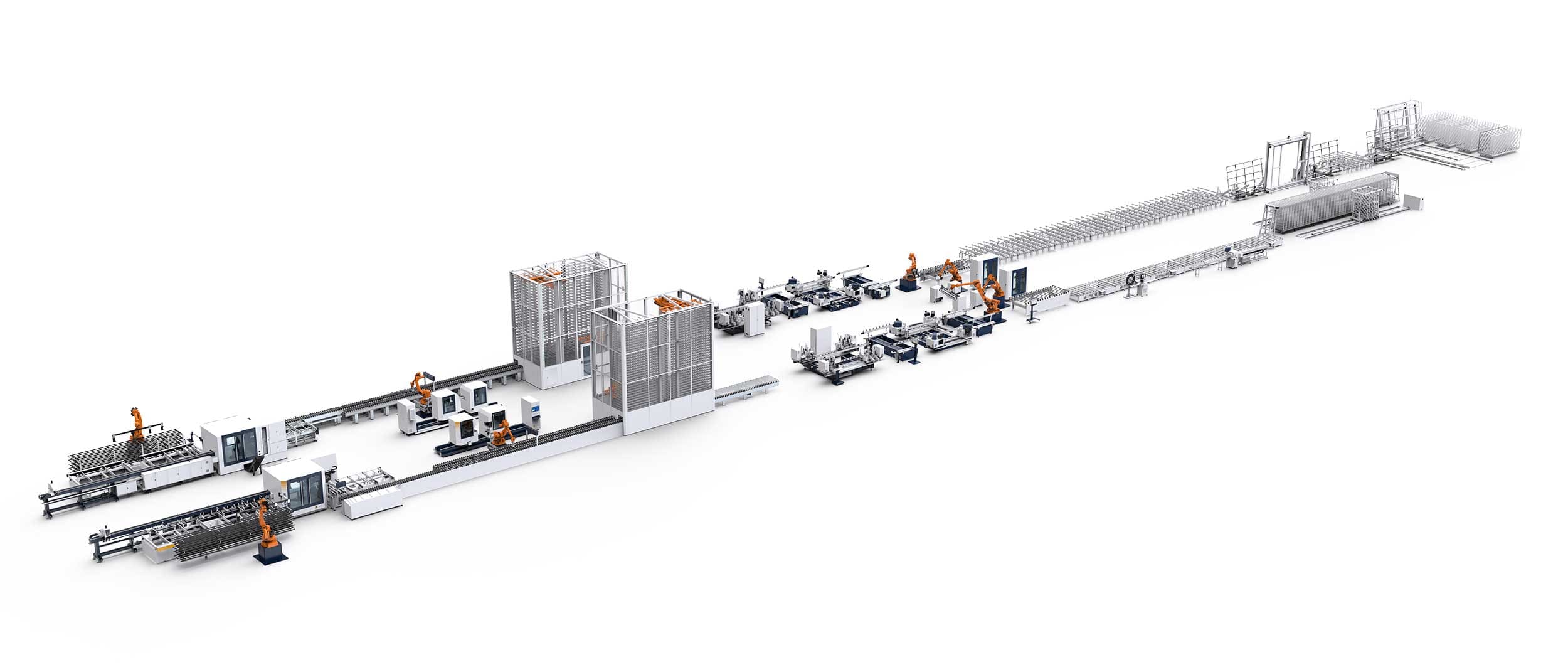

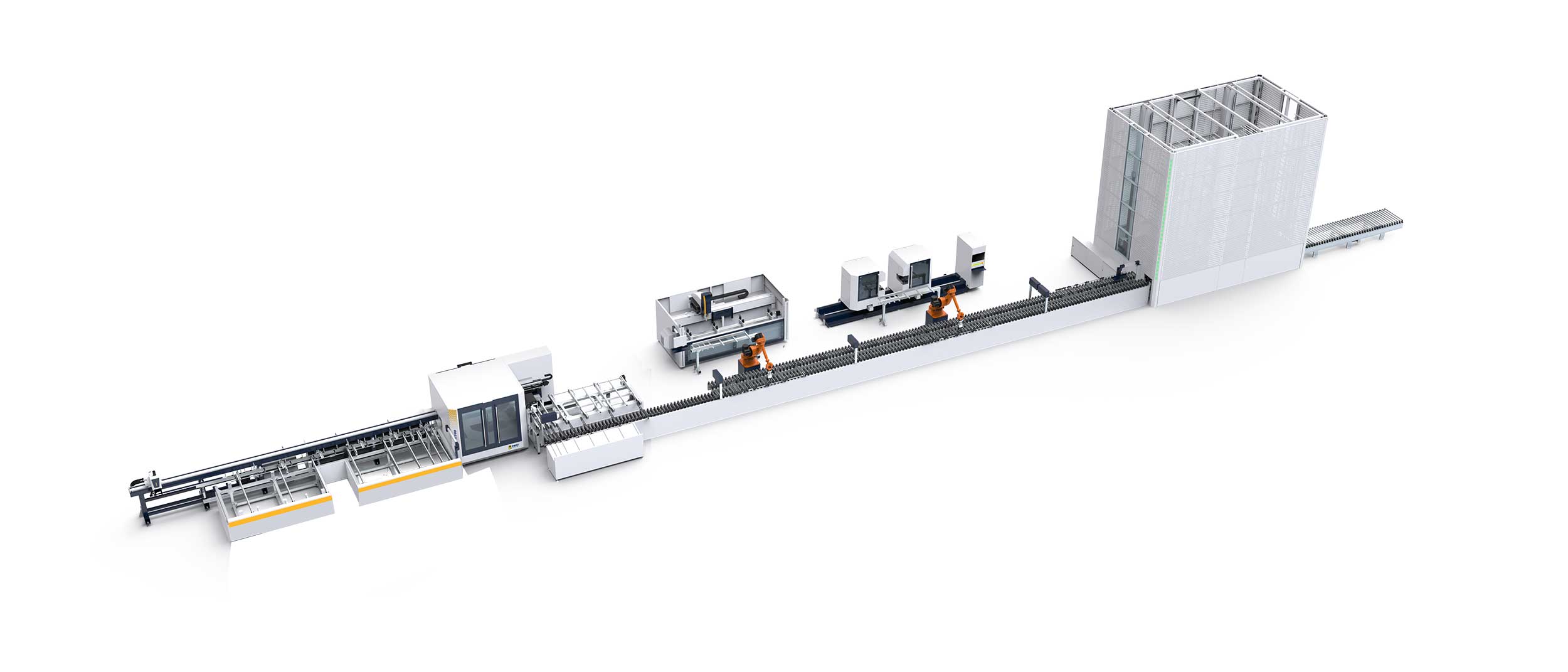

Smart Layout, Smart StartFactory planning & workflow optimization for peak efficiency

Dual-Line Power: Synced machining &assembly-2x productivity,zero bottlenecks.

Double Lines, Double Impact: Harmonized equipment for maximum throughput.

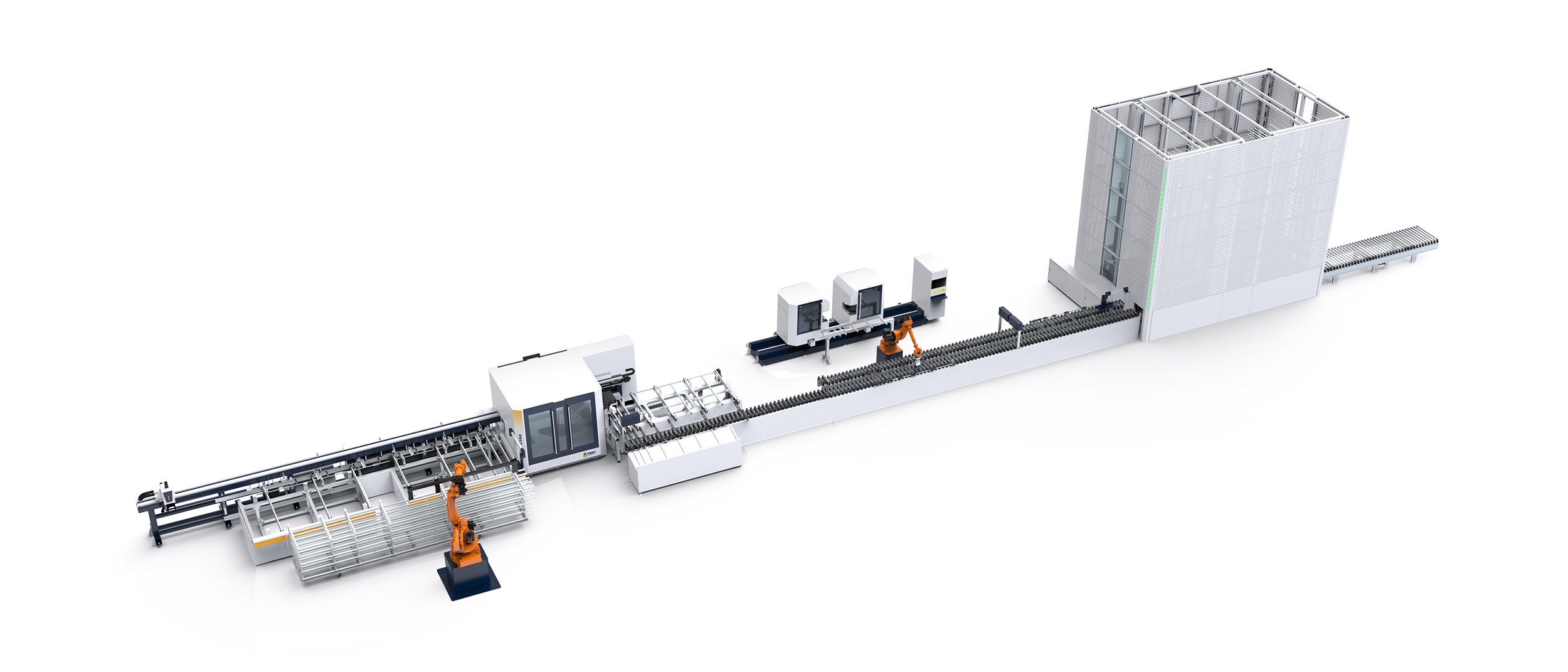

Designed to perform drilling, milling, sawing, and end milling operations for aluminum profiles, the S100 series streamlines production, boosts capacity, and minimizes labor costs through full automation.

The S200 series ensures detailed material flow organization, strict quality control, and reduced labor and management costs. Each profile is labeled with a sticker containing specifications and a QR code for traceability.

Ultra X380 – A high performance Cutting and Milling Machining Center for larger profile. Designed for Milling, Drilling, Cutting, and Laser Machining operations on the heads and ends of aluminum and light alloy larger profiles.

Designed for milling, drilling, cutting, and laser machining operations on aluminum and light alloy profiles, the UX260-E combines advanced automation, precision, and efficiency for modern manufacturing needs.

Designed for Milling, Drilling, Cutting, and Laser Machining operations on the heads and ends of aluminum and light alloy profiles.