Ultra X380 – A high performance Cutting and Milling Machining Center for larger profile.

| Machining Specifications | Parameter Value |

|---|---|

| Max. Profile Cross-Section | W×H = 385×200 mm |

| Min. Profile Cross-Section (depending on gripper position) | W×H = 30×20 mm |

| Raw profile length | L = 600–7,000 mm |

| Finished part length | L = 300–7,000 mm |

| Feed Magazine | Parameter Value |

|---|---|

| Number of swing arms | 4 |

| Mounting positions |

profile cross-section <250mm: 5 PCS

profile cross-section <380mm: 3 PCS

|

| Infeed | Parameter Value |

|---|---|

| Drive | Linear |

| Motorized gripper adjustment | Y/Z |

| Gripper rotation | Standard |

| Residual piece measurement | Optional |

| Residual piece processing | Fully automatic |

| Machining Station | Parameter Value |

|---|---|

| Axes | 31 |

| Router spindles | 4 (servo-assisted) |

| Saw | Parameter Value |

|---|---|

| Axes | 5 |

| Saw blades (diameter) | 550*1 4KW*1 |

| Sawing angles | 40°- 140°、 5-axis multidimensional angle |

| Notching | Saw diameter 350mm*1 |

| Outfeed Clamping Carriages | Parameter Value |

|---|---|

| Axis | 1 |

| Cycle operation (short parts) Laser | Optional |

| Outfeed Conveyor | Parameter Value |

|---|---|

| Lifting station | YES |

| Outfeed conveyor width | 4,000 mm (can be extended) |

| General Parameters | Parameter Value |

|---|---|

| Power supply | 400V/50Hz |

| Power | 39kw |

| Pressure | 0.5~0.8 Mpa |

| Gas consumption | 300 L/min |

| Weight | 11,900 kg |

| Overall dimensions |

21,000×5,500×2,800mm

(Including workbenches on both sides)

|

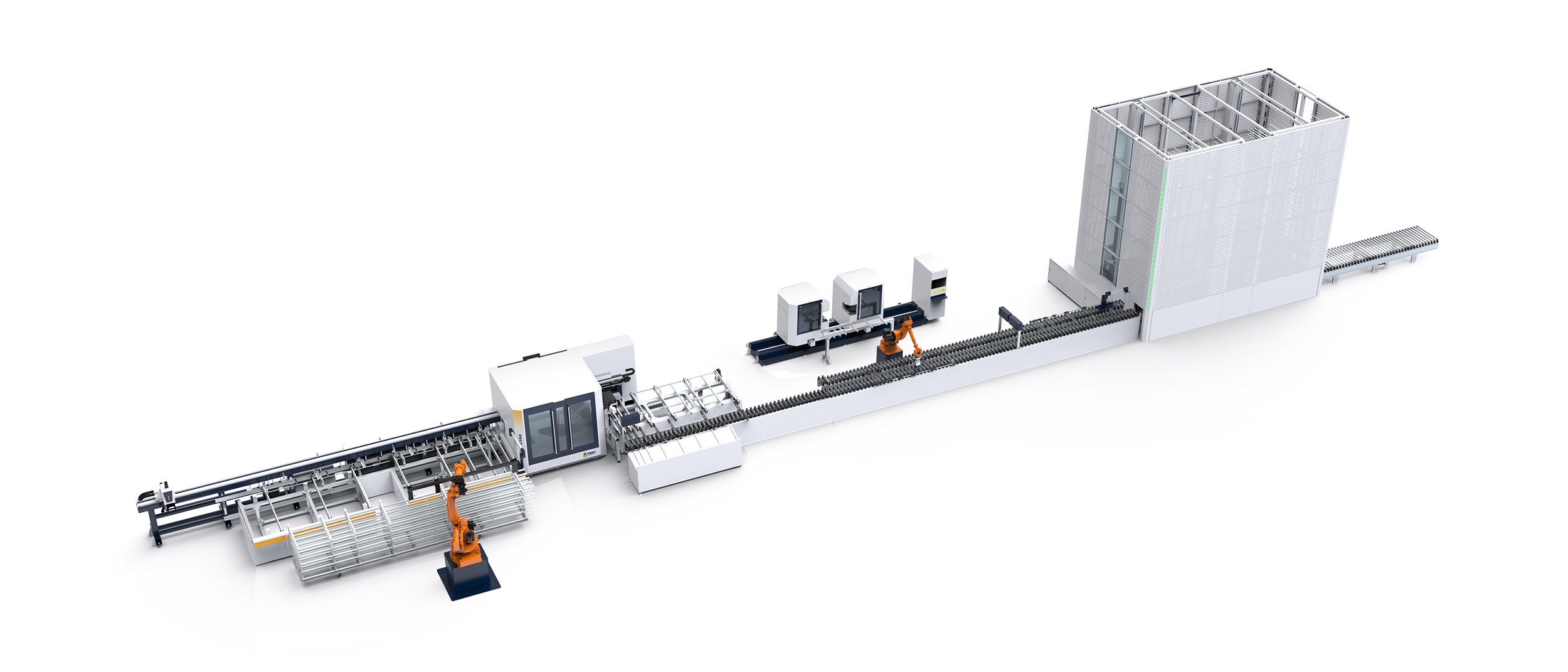

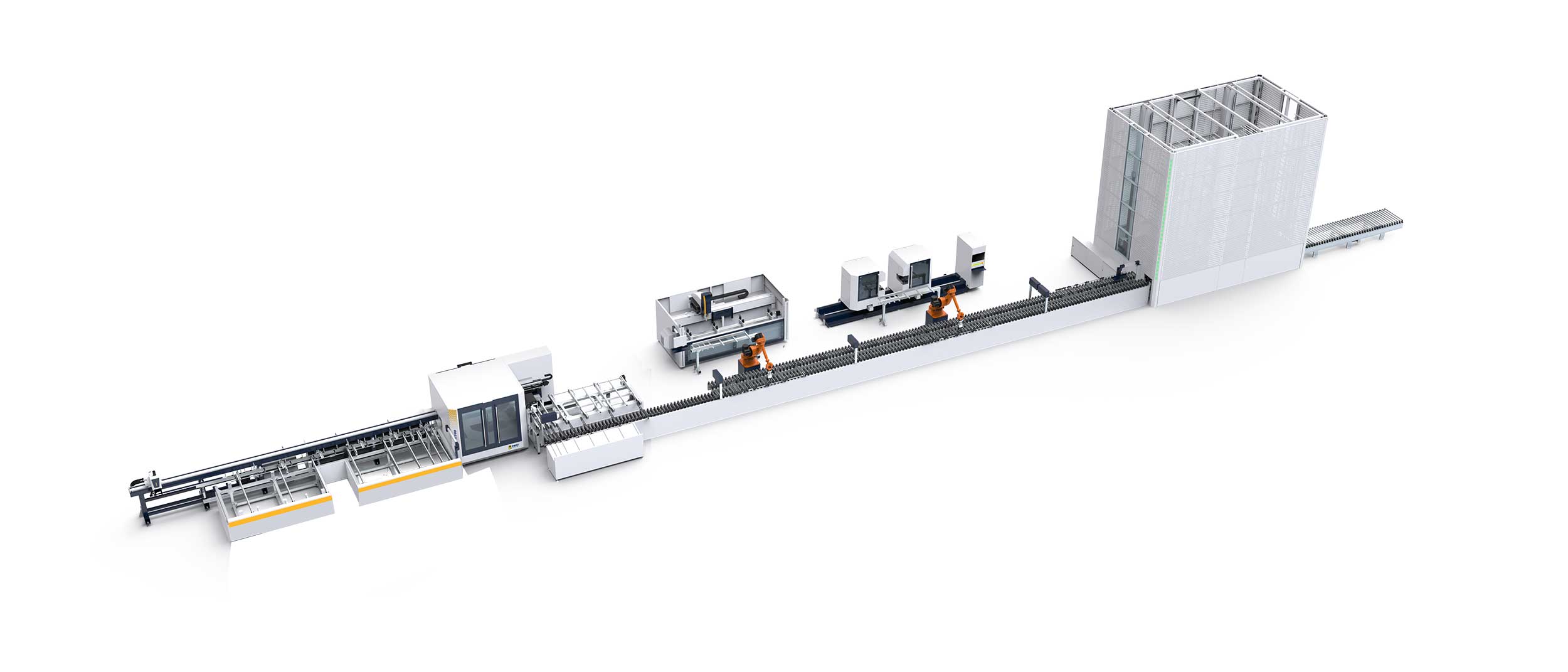

Designed to perform drilling, milling, sawing, and end milling operations for aluminum profiles, the S100 series streamlines production, boosts capacity, and minimizes labor costs through full automation.

Designed for milling, drilling, cutting, and laser machining operations on aluminum and light alloy profiles, the UX260-E combines advanced automation, precision, and efficiency for modern manufacturing needs.

The S200 series ensures detailed material flow organization, strict quality control, and reduced labor and management costs. Each profile is labeled with a sticker containing specifications and a QR code for traceability.

Designed for Milling, Drilling, Cutting, and Laser Machining operations on the heads and ends of aluminum and light alloy profiles.