6.2% annual growth in construction (2023) drives aluminum window demand, but 60% of factories still use semi-automated lines from the 2000s.

Legacy machines (e.g., 1990s cutting tools) operate at 25% the speed of modern IoT-enabled lines, with 15% downtime due to breakdowns.

Human errors cost 8–12% revenue (Deloitte):

±1.5mm measurement gaps → 15–20% material waste.

Hand-welding defects → 12% rejection rates (vs. 2% with robots).

Labor crisis: 23% of factories lack skilled workers for precision tasks.

Aluminum price swings (+42% YoY) and 8–12-week delays for key parts (e.g., thermal breaks) freeze production.

70% of Asian suppliers rely on 1–2 smelters; energy cuts or audits trigger shortages.

Automated lines with AI-driven scheduling slash idle time and maximize output:

German manufacturer AluTech achieved 4,200 units/day vs. 1,400 with legacy systems, cutting per-unit costs by 38%.

Robotic CNC cutting reduces cycle time from 90s to 22s per window frame (ABB Robotics data).

IoT sensors optimize energy use and prevent waste:

Thermal imaging detects motor overloads in real time, lowering electricity consumption by 18% (Siemens case study).

AI-powered predictive maintenance cuts unplanned repairs by 60%, saving $120K/year for a mid-sized U.S. fabricator.

Integrated redundancy and self-diagnosis ensure uninterrupted production:

Automatic tool-switching robots eliminate manual changeovers, maintaining <10s transition gaps (Fanuc deployment in Japan).

Cloud-based monitoring resolves 95% of faults remotely, reducing downtime to <4 hours/year (Rockwell Automation report).

LEADCNC's smart production line achieves efficient and stable operation around the clock through high automation, intelligent technology and system integration. The following is a detailed description of its core components and integration capabilities:

Import of production data

Software docking, connected with ERP software;

Can be imported via network/USB disk according to the material order format;

Can be directly input manually

Intelligent identification of profile data (height, wall thickness)

Intelligent adjustment of processing parameters (feed speed, feed position)

Save at least 3 skilled workers, saving about 240,000 labor costs each year

Completed production statistics

Equipment status and operation time statistics

Delivery date can be controlled in real time

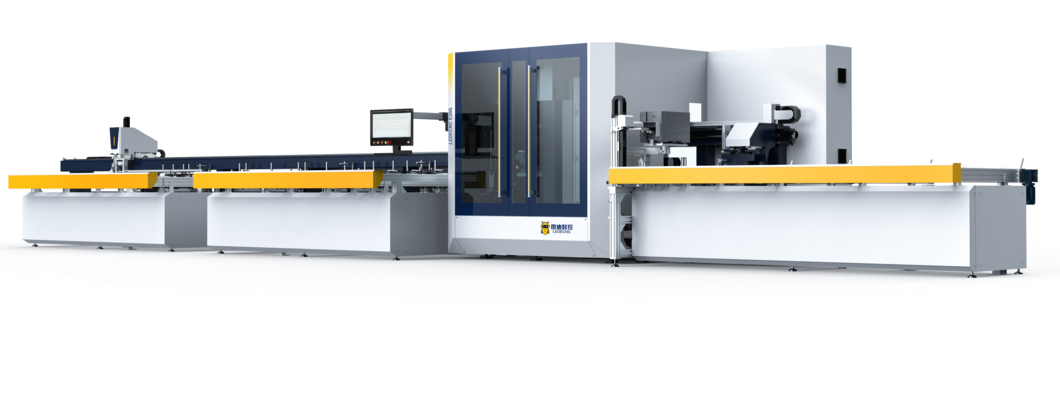

Designed to perform drilling, milling, sawing, and end milling operations for aluminum profiles, the S100 series streamlines production, boosts capacity, and minimizes labor costs through full automation.

The S200 series ensures detailed material flow organization, strict quality control, and reduced labor and management costs. Each profile is labeled with a sticker containing specifications and a QR code for traceability.

Production cycle reduced from 25-45 days to 7-12 days, efficiency increased by 300%

Ordinary workers can start after 2 hours of training, lowering labor barriers

Smart system achieves zero-error operation, with a yield rate of 99.9%

Daily output increased from 5-6㎡ to 8-10㎡, efficiency growth of 60%

Fivefold increase in output for the same space, monthly output reaching 15000㎡

Labor cost per square meter reduced from 58-98 yuan to about 25-35 yuan

Smart assembly line production eliminates internal process chaos and product堆积

Smart factory construction is easy to replicate and manage, enhancing competitiveness

Manufacturing costs reduced by 8%-10% compared to traditional factories

Smart factory construction is a powerful tool for successful investment attraction

As one of the eight regional manufacturing centers established by Xuge in China, Shanghai SMICK has an intelligent factory of 4000 square meters, equipped with an intelligent production line of Reid CNC door and window industrial 4.0, providing more efficient production and service for Xuge door and window products.

Huangpai doors and windows have been re-purchased for 4 consecutive years by Reid CNC tens of millions of intelligent production lines, providing guarantee for efficient quality delivery.

On September 26, 4 Reid CNC S series door and window intelligent production lines were successfully delivered to SAYYAS Harbin factory, marking the beginning of cooperation between the two sides again.

Learn how to operate a lathe with this all-in-one beginner’s guide—covering safety, tools, setup, and expert tips. Perfect for DIYers, machinists, and students! Start turning like a pro today.

Discover the top 10 aluminium doors and windows manufacturers in China for 2025, including OPPEIN, Mannlee, and Paiya. Explore their innovative aluminium solutions, from energy-efficient windows to luxury doors, backed by LEADCNC’s advanced production lines.

Discover the unbeatable power of CNC machine centers for aluminum processing. LEADCNC’s Ultra X380 & Emerald F550 deliver 0.1mm precision for doors, windows, and more. Explore types, benefits, and why we dominate!

Rising costs and delays killing your CNC door & window profits? Upgrade to a smart window production line with LEADCNC to survive 2025!