_1742960820_WNo_1600d900.webp)

Aluminum’s lightweight strength and versatility make it a vital material in industries like construction, automotive, and aerospace. To harness its potential, you need a top-tier CNC machine for aluminium that ensures precision, efficiency, and durability. At LeadCNC, with over a decade of expertise in CNC manufacturing and exports to 70+ countries, we’ve crafted this guide to help you select the perfect machine. From technical specs to real-world applications, here’s everything you need to know in 2025.

Aluminum’s unique properties—softness, high thermal conductivity, and a tendency to adhere to cutting tools—demand specialized equipment. For instance, alloys like 6061-T6, popular in structural applications, require high spindle speeds and robust cooling to avoid tool wear and maintain surface quality. Without the right CNC machine for aluminium, you risk poor finishes, excessive waste, or even machine damage.

The global aluminum CNC machining market is booming, projected to hit $129.9 billion by 2027 with a CAGR of 6.8% (Uptive, 2024). This growth underscores the need for advanced machines tailored to aluminum’s challenges.

Selecting the right machine means focusing on features that optimize aluminum processing. Based on our experience at LeadCNC and industry benchmarks, here are the must-haves:

Aluminum thrives on high-speed machining—spindle speeds of 30,000 RPM or more are ideal for clean cuts and minimal heat buildup. Hobbyist machines like the Inventables X-Carve suffice for small projects, but industrial tasks demand more. LeadCNC’s CNC machines for aluminium deliver up to 40,000 RPM, ensuring efficiency for large-scale production.

Vibration can ruin aluminum parts, especially thin sheets or intricate designs. A rigid frame is non-negotiable. Our machines, backed by 200+ national patents, use reinforced structures to eliminate chatter, delivering precision down to 0.1mm—perfect for aluminum window frames or automotive components.

Tools matter as much as the machine. Carbide tools with ZrN coatings reduce friction and excel at chip removal. Cutting-edge options like Mapal’s OptiMill-Alu-Wave (AMFG, 2024) set the standard. LeadCNC machines pair seamlessly with these tools for superior results.

AI-driven software is revolutionizing CNC machining. Tools like CloudNC’s CAM Assist cut programming time by up to 300 hours annually. LeadCNC integrates intelligent control systems, streamlining workflows and boosting productivity for aluminum projects.

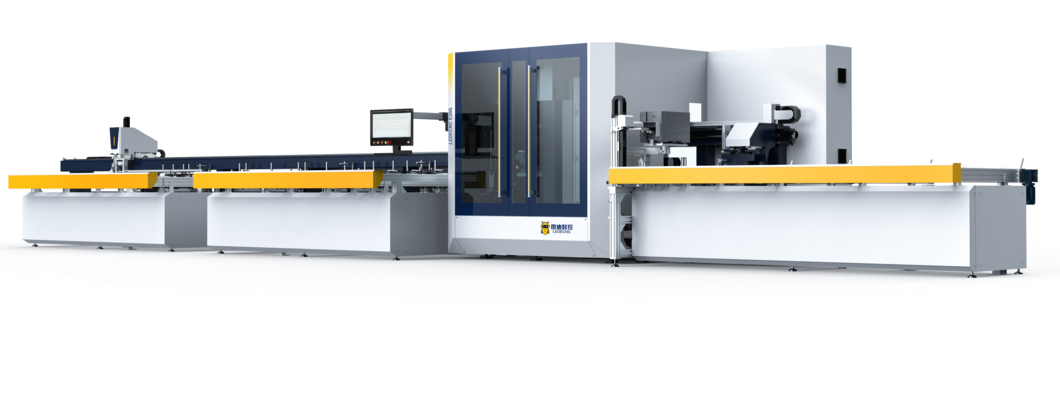

With over 10 years of experience, LeadCNC specializes in CNC machines for aluminium, particularly for profile processing in window and door manufacturing. Our equipment, exported globally, achieves precision within 0.1mm and supports high-volume production with minimal downtime.

Real-World Case Study: A European aluminum window manufacturer switched to a LeadCNC Smart Aluminum Window Production Line in 2024. The result? A 25% increase in output, 15% less waste, and a smoother finish that won client praise. Watch the process in action:

Our commitment to innovation—evidenced by 200+ patents—ensures we meet the toughest industry standards. Visit our product page to see how we can elevate your operations.

Maximize your CNC machine for aluminium with these expert tips, drawn from our team’s hands-on experience:

The industry is evolving fast. Here’s what’s shaping aluminum machining in 2025:

LeadCNC stays ahead by integrating these trends, ensuring our CNC machines for aluminium remain cutting-edge. Check out our latest innovations on YouTube.

Not all machines are equal. Here’s how LeadCNC stacks up:

| Feature | LeadCNC | Typical Hobbyist Machine |

|---|---|---|

| Spindle Speed | Up to 40,000 RPM | 10,000-20,000 RPM |

| Precision | 0.1mm | 0.5mm |

| Best For | Industrial Aluminum Profiles | Small DIY Projects |

Choosing the best CNC machine for aluminium means prioritizing speed, rigidity, and smart technology. Whether you’re crafting precision parts or scaling production, LeadCNC delivers unmatched quality. Explore our solutions at LeadCNC Products, or reach out to our expert team.

Ready to transform your aluminum machining? Trust LeadCNC—where expertise meets innovation.

Learn how to operate a lathe with this all-in-one beginner’s guide—covering safety, tools, setup, and expert tips. Perfect for DIYers, machinists, and students! Start turning like a pro today.

Discover the top 10 aluminium doors and windows manufacturers in China for 2025, including OPPEIN, Mannlee, and Paiya. Explore their innovative aluminium solutions, from energy-efficient windows to luxury doors, backed by LEADCNC’s advanced production lines.

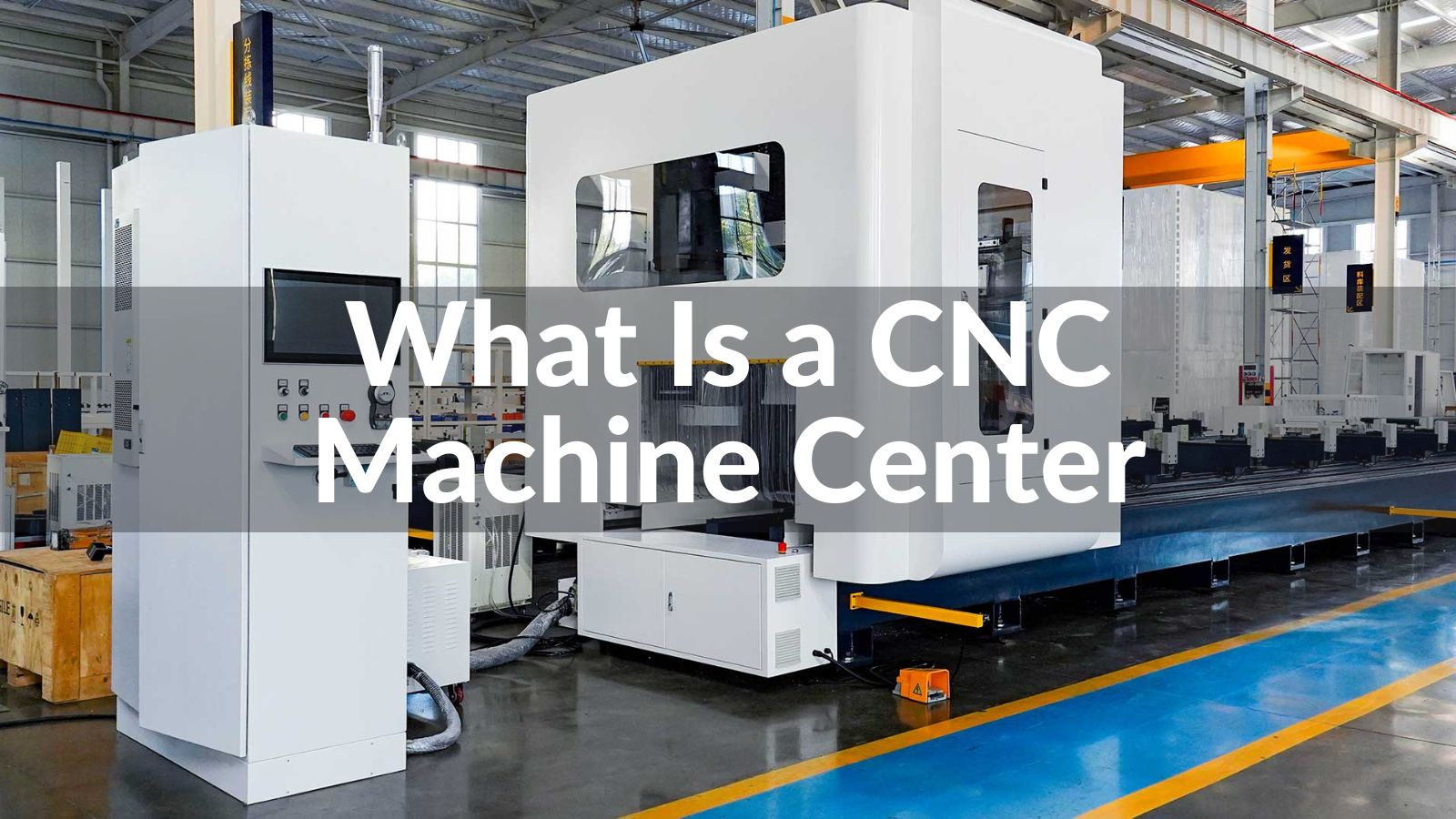

Discover the unbeatable power of CNC machine centers for aluminum processing. LEADCNC’s Ultra X380 & Emerald F550 deliver 0.1mm precision for doors, windows, and more. Explore types, benefits, and why we dominate!

Rising costs and delays killing your CNC door & window profits? Upgrade to a smart window production line with LEADCNC to survive 2025!