In 2025, traditional CNC door and CNC window factories are on the brink. Rising costs have surged 15%-20% due to material price hikes and labor shortages, while production delays cost you clients daily (Aeroseal Windows). If your window production line clings to outdated tech, you’re losing more than just profits—you’re losing your future. A smart window production line from LEADCNC could be your lifeline. Ready to face the numbers?

Manual errors in CNC window and CNC door production waste 10%-15% of raw materials—that’s up to $50,000 annually for a mid-sized factory (LinkedIn: Overcoming Challenges). Each defective CNC window triggers rework costs of $20-$30 per unit, plus lost trust from clients demanding ISO 9001-compliant quality. Your window production line can’t keep bleeding like this.

Over 60% of CNC door and window factories can’t find skilled workers in 2025, up from 50% in 2022 (2022 Industry Pulse Report). Training new hires takes 3-6 months, delaying your window production line by up to 20%. Meanwhile, labor costs have spiked 12% since 2023, squeezing your margins on every CNC door.

Supply chain chaos isn’t slowing down—70% of window production line projects faced delays in 2024, with aluminum prices jumping 18% year-over-year (Aeroseal Windows). For a typical CNC door, that’s an extra $15-$25 per unit. Can your CNC window factory absorb these hits?

Traditional window production lines take 30%-40% longer on custom CNC door and CNC window orders compared to smart systems (L2L Smart Manufacturing). With clients expecting 7-10 day delivery—a standard set by leaders like Pella—your slow CNC window output risks losing 25% of your contracts to faster rivals.

New Energy Star 7.0 standards demand U-factors below 0.27 for windows by 2026 (Window + Door). Non-compliant CNC window factories face $10,000+ in fines or market bans. Retrofitting old window production lines costs $50,000-$100,000—money you might not have.

Do nothing, and your CNC door and window factory faces a grim fate. Competitors with smart window production lines are cutting costs by 20% and delivering CNC windows 30% faster. Industry forecasts warn that 35% of traditional factories may shutter by 2027 if they don’t adapt. Rising costs aren’t a trend—they’re your breaking point.

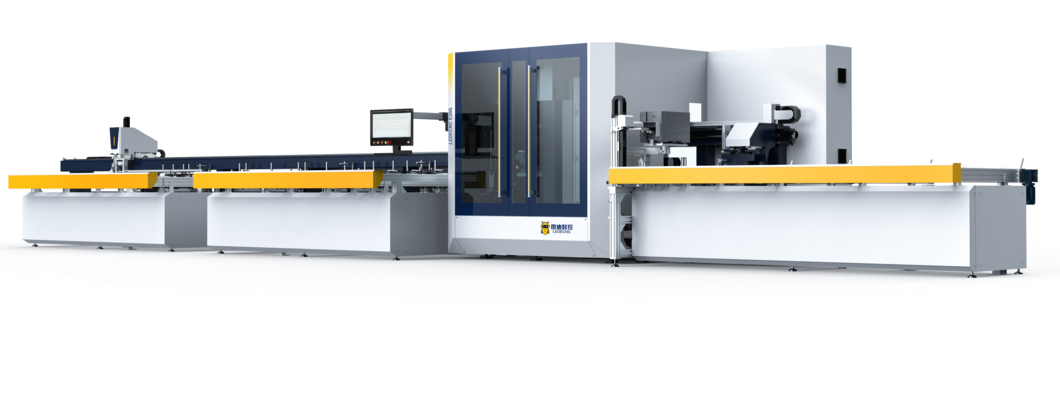

A smart window production line with CNC tech, AI, and IoT tackles every pain point:

Pinpoint Accuracy: CNC window cuts to 0.1mm precision, slashing waste by 30% (LEADCNC Features).

Speed Surge: Boosts window production line output by 25%-35%, no extra labor needed.

Cost Slash: Drops CNC door production costs by 15%-20% through automation.

Custom Ready: Adapts to bespoke CNC window orders in hours, not days.

Compliance Built-In: Meets Energy Star and ISO 9001 standards effortlessly.

As one of the eight regional manufacturing centers established by Xuge in China, Shanghai SMICK has an intelligent factory of 4000 square meters, equipped with an intelligent production line of Reid CNC door and window industrial 4.0, providing more efficient production and service for Xuge door and window products.

Huangpai doors and windows have been re-purchased for 4 consecutive years by Reid CNC tens of millions of intelligent production lines, providing guarantee for efficient quality delivery.

On September 26, 4 Reid CNC S series door and window intelligent production lines were successfully delivered to SAYYAS Harbin factory, marking the beginning of cooperation between the two sides again.

LEADCNC powers CNC door and window production lines with 200+ patents and exports to 70+ countries. Their systems deliver 0.1mm precision and 30% efficiency gains, trusted by global leaders. Contact sales001@leadcnc.com to save your CNC window factory now.

Rising costs, delays, and regulations are choking your CNC door and window factory. A smart window production line from LEADCNC cuts costs, boosts output, and keeps you competitive. Visit their site today—don’t let 2025 be your last year in CNC window production.

Learn how to operate a lathe with this all-in-one beginner’s guide—covering safety, tools, setup, and expert tips. Perfect for DIYers, machinists, and students! Start turning like a pro today.

Discover the top 10 aluminium doors and windows manufacturers in China for 2025, including OPPEIN, Mannlee, and Paiya. Explore their innovative aluminium solutions, from energy-efficient windows to luxury doors, backed by LEADCNC’s advanced production lines.

Discover the unbeatable power of CNC machine centers for aluminum processing. LEADCNC’s Ultra X380 & Emerald F550 deliver 0.1mm precision for doors, windows, and more. Explore types, benefits, and why we dominate!

Rising costs and delays killing your CNC door & window profits? Upgrade to a smart window production line with LEADCNC to survive 2025!