Imagine a world where your doors and windows are crafted with precision, speed, and intelligence—all thanks to cutting-edge technology. By 2025, the rise of AI alloy door window production lines promises to transform the manufacturing landscape, blending automation and artificial intelligence (AI) to create smarter, more efficient systems. Whether you’re a homeowner dreaming of sleek alloy designs or a business owner looking to streamline production, this revolution is knocking at your door. In this article, we’ll explore how automated alloy door production in 2025 is set to redefine the industry, why it matters, and what it means for you. From boosting efficiency to slashing costs, AI in window manufacturing is no longer a distant dream—it’s the future unfolding now.

By 2025, automation isn’t just a buzzword—it’s a necessity. The manufacturing sector, including alloy door and window production, is racing toward smarter systems powered by AI. Why? Because traditional methods can’t keep up with rising demand, stricter quality standards, and the need for sustainability. Experts predict that AI alloy door window production lines will drive a 30% increase in efficiency by 2025, thanks to machines that learn, adapt, and optimize in real time. This shift isn’t just about speed; it’s about precision and scalability, making automated alloy door production in 2025 a game-changer for businesses big and small.

Today’s consumers want products that are durable, stylish, and affordable. Alloy doors and windows—made from lightweight, strong materials like aluminum—fit the bill, but producing them manually is slow and costly. Automation, paired with AI, ensures that manufacturers can meet these demands without compromising quality. Curious about how this works? Let’s dive deeper into the benefits.

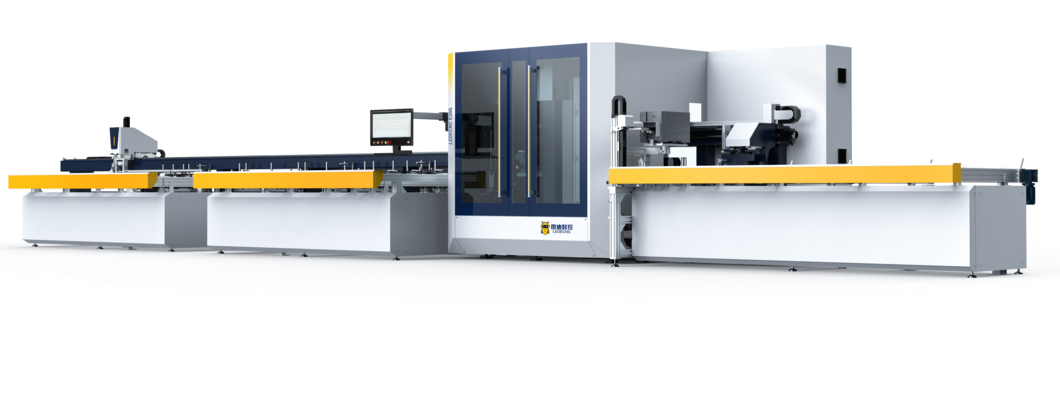

Picture this: a factory where machines predict errors before they happen, adjust settings on the fly, and churn out flawless alloy frames. That’s the power of AI in window manufacturing. By integrating sensors and data analytics, AI alloy door window production lines can monitor every step—cutting, welding, assembling—and fine-tune the process instantly. For example, an AI system might detect a slight misalignment in a door frame and correct it in seconds, saving time and materials. Industry forecasts suggest that such systems could reduce production time by up to 25% by 2025.

One of the biggest perks of automated alloy door production in 2025 is cost savings. Manual labor is expensive, and human errors can lead to wasted resources. AI-driven machines, on the other hand, work tirelessly with minimal supervision, slashing labor costs while maintaining top-notch quality. For businesses, this means higher profits; for consumers, it translates to more affordable, high-quality alloy doors and windows.

Ever noticed how some doors fit perfectly while others squeak or stick? That’s often the result of inconsistent production. AI eliminates this problem by ensuring every piece meets exact specifications. Whether it’s a sleek window frame or a sturdy alloy door, future alloy production lines powered by AI deliver uniformity that humans alone can’t achieve. This consistency builds trust—and sales—for manufacturers.

Let’s take a peek at a hypothetical factory in 2025. The day starts with an order for 100 custom alloy windows. The AI alloy door window production line springs into action:

This isn’t science fiction; it’s the future of alloy production lines already taking shape in advanced facilities worldwide.

Consider a small manufacturer struggling to compete with larger rivals. By adopting an AI in window manufacturing system in 2025, they double their output without hiring extra staff. The AI spots inefficiencies—like overuse of raw materials—and suggests tweaks that save 15% on costs. Soon, they’re landing bigger contracts, all thanks to automation. Stories like this show how automated alloy door production in 2025 levels the playing field.

As one of the eight regional manufacturing centers established by Xuge in China, Shanghai SMICK has an intelligent factory of 4000 square meters, equipped with an intelligent production line of Reid CNC door and window industrial 4.0, providing more efficient production and service for Xuge door and window products.

Huangpai doors and windows have been re-purchased for 4 consecutive years by Reid CNC tens of millions of intelligent production lines, providing guarantee for efficient quality delivery.

On September 26, 4 Reid CNC S series door and window intelligent production lines were successfully delivered to SAYYAS Harbin factory, marking the beginning of cooperation between the two sides again.

Adopting AI alloy door window production lines isn’t just about keeping up—it’s about staying ahead. Companies that embrace this tech can scale faster, reduce waste, and offer competitive pricing. Plus, with sustainability on everyone’s mind, AI’s ability to optimize resources makes it a green choice too. Analysts estimate that by 2025, 40% of alloy manufacturers will rely on automated systems, leaving late adopters scrambling to catch up.

For homeowners and builders, the rise of future alloy production lines means access to premium alloy doors and windows at lower costs. Imagine upgrading your home with energy-efficient, custom-fit windows that didn’t break the bank—all made possible by AI precision. Plus, faster production times mean shorter waits for deliveries. It’s a win-win.

The future of alloy production lines ties into broader trends. By 2025, AI isn’t just an add-on—it’s the backbone of manufacturing. From predictive maintenance (fixing machines before they break) to supply chain optimization, AI’s role is expanding. Pair that with automation, and you’ve got a recipe for a smarter, leaner industry.

Alloy production isn’t just about profit—it’s about planet too. AI systems can reduce energy use by optimizing workflows, while automation cuts down on material waste. As eco-conscious consumers demand greener options, AI alloy door window production lines offer a sustainable edge that resonates in 2025 and beyond.

So, where does this leave us? The automated alloy door production in 2025 wave is coming fast, powered by AI that’s smarter than ever. For businesses, it’s a chance to innovate and thrive. For consumers, it’s a promise of better products at better prices. But one question remains: Are you prepared to embrace this intelligent revolution? The AI in window manufacturing era isn’t waiting—it’s here, reshaping how we build the spaces we live in.

Want to know more about how AI alloy door window production lines could transform your home or business? Keep following our updates for the latest insights and tips!

Learn how to operate a lathe with this all-in-one beginner’s guide—covering safety, tools, setup, and expert tips. Perfect for DIYers, machinists, and students! Start turning like a pro today.

Discover the top 10 aluminium doors and windows manufacturers in China for 2025, including OPPEIN, Mannlee, and Paiya. Explore their innovative aluminium solutions, from energy-efficient windows to luxury doors, backed by LEADCNC’s advanced production lines.

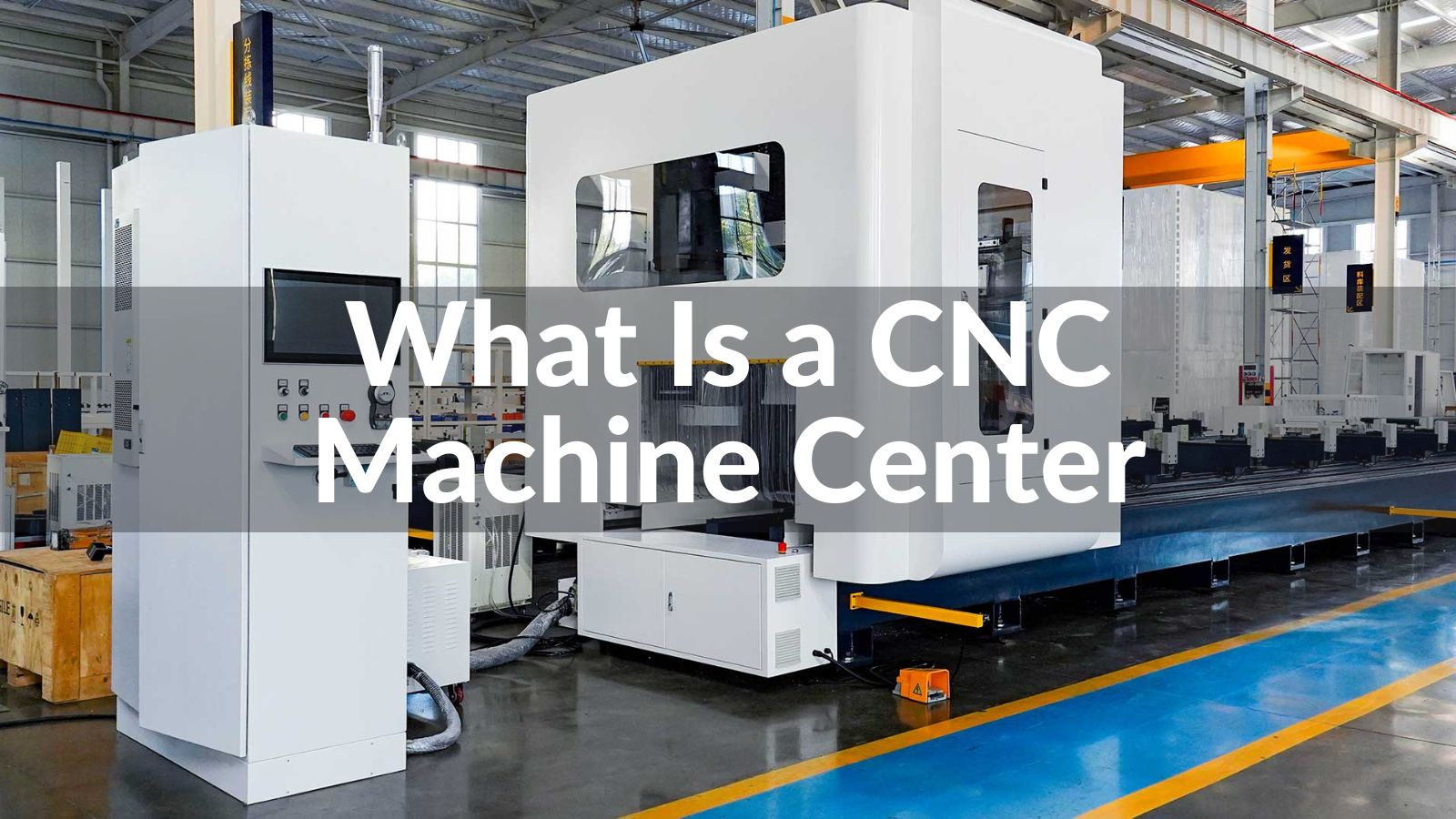

Discover the unbeatable power of CNC machine centers for aluminum processing. LEADCNC’s Ultra X380 & Emerald F550 deliver 0.1mm precision for doors, windows, and more. Explore types, benefits, and why we dominate!

Rising costs and delays killing your CNC door & window profits? Upgrade to a smart window production line with LEADCNC to survive 2025!