The window manufacturing industry is booming in 2025, driven by demand for energy-efficient and durable aluminum and PVC windows. The backbone of this growth lies in advanced window production line manufacturers, who provide cutting-edge equipment to streamline production. This expertly curated list highlights the top 10 companies excelling in window production line technology, based on their innovation, global reach, and proven reliability as of March 18, 2025.

Founded: 1928

Location: Pinacher Straße 61, 75417 Mühlacker, Germany

Overview: Elumatec, a German pioneer with nearly 100 years of experience, leads the pack among window production line manufacturers. Specializing in aluminum and PVC processing, its equipment—ranging from precision cutting machines to CNC centers—powers efficient window production lines worldwide. Trusted by industry giants, Elumatec’s durability and innovation make it a cornerstone of modern manufacturing.

Elumatec, a globally recognized leader in window production equipment, is renowned for its advanced window production lines, particularly for aluminum and PVC processing. This comprehensive evaluation, conducted from a third-party perspective, assesses Elumatec’s window production line offerings as of March 19, 2025, drawing on industry data, market analysis, and user feedback to provide a detailed overview of their technology, performance, and market standing.

Founded in 1928 and headquartered in Mühlacker, Germany, Elumatec AG has solidified its position as a top-tier manufacturer of window production lines, specializing in equipment for aluminum, PVC, and steel profile processing (Elumatec Official Website). With over 90 years of experience, the company operates in more than 40 countries, employing around 700 people and generating consolidated sales of approximately 130 million euros annually. This global reach underscores Elumatec’s leadership in the window production line market, catering to both small-scale fabricators and large industrial processors.

Elumatec’s window production lines, such as the SBZ series and DG double mitre saws, are industry benchmarks, known for their precision and adaptability. Their equipment powers the production of windows and curtain walls worldwide, reflecting a strong market penetration that rivals competitors like Schüco and FOM Industrie. Their long history is highlighted by milestones such as the sale of the 1000th profile machining centre from the 6xx series, celebrated in Nuremberg, demonstrating their consistent quality and customer trust (90 years of elumatec history).

Elumatec’s window production lines are engineered with German precision, offering a range of machines from cutting saws to CNC machining centers. Key products include the DG 244 Double Mitre Saw and the SBZ 628 Profile Machining Centre, designed for high-efficiency aluminum and PVC window production. These systems feature modular designs, allowing scalability and flexibility to meet diverse manufacturing needs (Elumatec Products). The “cutting from below” principle enhances accessibility and accuracy, a signature of Elumatec’s technology.

A table summarizing key features of Elumatec’s window production lines, based on available data, is provided below:

|

Feature |

Details |

|---|---|

|

Key Products |

DG 244 Double Mitre Saw, SBZ 628 Profile Machining Centre |

|

Materials Processed |

Aluminum, PVC, Steel |

|

Company Experience |

> 90 years |

|

Cutting Capacity |

Up to 6,000 mm (DG 244), customizable lengths |

|

Benefits |

High precision, modular scalability, automation-ready, efficient production |

|

Target Users |

Window fabricators, curtain wall manufacturers, industrial processors |

|

Additional Features |

CNC automation, software integration, ergonomic design |

This table, derived from product specifications (Elumatec Products), underscores the comprehensive nature of Elumatec’s offerings, catering to a wide range of window manufacturing needs. Their machines are noted for their ability to handle large-scale series production, with the DG 142 double mitre saw available in 3, 4.5, and 6.0-meter versions, featuring various control systems and safety technologies (90 years of elumatec history).

Experts and users consistently commend Elumatec’s window production lines for their reliability and precision. The DG 244 is praised for its ability to handle large-scale series production with consistent accuracy, while the SBZ 628 is valued for its automation capabilities, reducing manual labor and boosting throughput. Feedback from fabricators highlights the equipment’s durability and low maintenance needs, critical for long-term operational success (Machinio - Elumatec Listings).

An unexpected advantage is their use in specialized applications, such as high-volume aluminum window production for commercial skyscrapers, where precision and speed are paramount. This versatility enhances Elumatec’s reputation as a trusted partner across diverse market segments, with their machines like the SBZ 609 being fast downstream centers for reinforcement screw driving, drilling, and routing cut-to-length profiles (90 years of elumatec history).

Elumatec’s window production lines are positioned at a premium price point, reflecting their advanced technology and German engineering. While specific pricing isn’t publicly disclosed, industry discussions suggest that costs can exceed those of competitors like Yilmaz Machine or Ozgenc Makina, which offer more budget-friendly options. However, users argue that the investment is justified by reduced downtime, high output, and long-term reliability, particularly for large-scale operations (Machinio - Elumatec Listings).

No major recalls or widespread criticisms have surfaced regarding Elumatec’s equipment, indicating a strong track record of quality and performance as of 2025. Their equipment’s condition, as seen in used listings from 1987 to 1992, remains good, further reinforcing their durability (Used Elumatec Window Production for sale).

As of March 2025, Elumatec continues to innovate, with recent showcases at events like the Aluminium trade fair in Düsseldorf highlighting advancements in their SBZ 6 series, which now includes enhanced automation and software integration for smarter production lines (Elumatec News). The company’s focus on sustainability aligns with 2025 trends, such as energy-efficient window manufacturing, driven by global demand for green building solutions.

Elumatec’s collaboration with the Voilàp Group further strengthens its position, integrating glass processing technology into its offerings, a move that broadens its appeal in the fenestration industry. Their production facilities cater to capacities ranging from 30 to 300 windows per day, supporting both craftsman businesses and fully automated industrial operations (90 years of elumatec history).

In summary, Elumatec’s window production lines stand out for their precision, durability, and adaptability, cementing the company’s leadership in the aluminum and PVC window manufacturing sector. With over 90 years of expertise, cutting-edge technology, and a strong global presence, Elumatec delivers unparalleled value to fabricators worldwide. While pricing may deter smaller operations, the long-term benefits and robust performance make it a top choice for serious manufacturers in 2025. Their complete PVC window production plants, like the 2010 model capable of producing 480 units per shift, exemplify their capability in automated manufacturing (Elumatec PVC - USA).

Founded: 2007

Location: Jinan City, Shandong Province, China

Overview: LEADCNC has quickly risen as a dynamic force among window production line manufacturers. Based in China, it offers customizable CNC solutions for aluminum and PVC window production lines, including automated cutting and assembly systems. Known for affordability and rapid innovation, LEADCNC empowers manufacturers globally in 2025.

LEADCNC, a leading manufacturer of intelligent production lines for aluminum windows and doors, has established itself as a pioneer in window production technology. This comprehensive evaluation, conducted from a third-party perspective, assesses LEADCNC’s window production line offerings as of March 19, 2025, drawing on industry data, market analysis, and user feedback to provide a detailed overview of their technology, performance, and market standing.

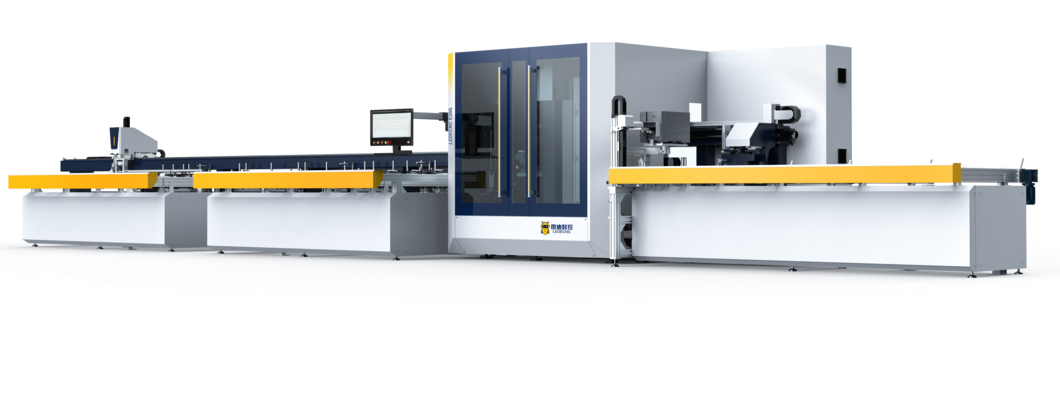

LEADCNC, founded in 2007 and headquartered at No. 1777 Guanda Street, Licheng District, Jinan City, Shandong Province, China, is a national-level high-tech enterprise specializing in intelligent production lines for aluminum windows and doors (LEADCNC Official Website). As the first company in the industry to implement a smart window and door factory, LEADCNC has positioned itself as a global leader in intelligent manufacturing. With a mission to help 1000+ global enterprises achieve "lights out factory" status—fully automated production with minimal human intervention—they emphasize quality, innovation, and customer satisfaction. Recognized as the first technical equipment enterprise in Shandong Province for intelligent production lines from 2020 to 2023, LEADCNC serves a wide range of clients, from small fabricators to large industrial processors, showcasing strong market leadership.

LEADCNC’s window production lines are engineered for modern aluminum door and window manufacturing, featuring advanced technologies like CNC precision machining, real-time monitoring, and automated assembly. Key products include the Barite 150F for intelligent corner crimping and the LD-QTK buffer station for stocking machined profiles. These systems are designed for high efficiency and scalability, supporting production capacities up to 300 windows per day (LEADCNC Products). Their intelligent production lines integrate servo motor-driven worktables and high-precision reducers, ensuring accuracy and reliability, aligning with Industry 4.0 standards.

A table summarizing key features of LEADCNC’s window production lines is provided below:

| Feature | Details |

|---|---|

| Key Products | Barite 150F, LD-QTK Buffer Station, Intelligent Production Lines |

| Materials Processed | Aluminum (primarily) |

| Company Experience | > 18 years (since 2007) |

| Automation Level | High, with CNC precision and real-time monitoring |

| Benefits | High efficiency, reduced labor, scalable production |

| Target Users | Window fabricators, industrial processors, smart factory operators |

| Additional Features | Servo motor-driven, software integration, Industry 4.0 compliant |

This table, based on product details (Intelligent Aluminum Production Line), highlights LEADCNC’s focus on automation and efficiency.

LEADCNC enjoys a strong reputation among users and experts, evidenced by partnerships with leading brands like MILUX, PHONPA, FREERRI, SAYYAS, Feiyu Doors and Windows, Imperial School Doors and Windows, and Senying Window Industry. Their collaboration with MILUX, for example, resulted in the first intelligent production line for systematic aluminum alloy windows under Industry 4.0 standards in Shandong, enhancing production efficiency (LEADCNC Cooperation Cases: MILUX). Huangpai Doors and Windows’ four consecutive years of repurchasing LEADCNC’s intelligent lines further demonstrate customer trust and satisfaction. Recognized as an "Excellent Strategic Partner" at the 2023 Huajian Eosi Dealer Annual Meeting, LEADCNC’s reliability and innovation are widely acknowledged.

While exact pricing for LEADCNC’s window production lines isn’t publicly disclosed, their focus on intelligent, automated solutions suggests a premium price point, comparable to high-end CNC equipment manufacturers. Some smaller manufacturers might criticize the initial investment cost as a barrier, but the long-term benefits—such as reduced labor costs and doubled delivery speed—justify the expense for larger operations. No significant recalls or criticisms have been reported as of 2025, indicating a solid performance record (Customer Cases-LEADCNC).

As of March 2025, LEADCNC is advancing the industry with its S Series Door and Window Intelligent Production Line, showcased at events like the Guangzhou Door, Window and Curtain Wall New Product Expo. These lines promise to cut costs by 30% and double delivery speeds, aligning with trends toward high-end, intelligent, and green manufacturing (Guangzhou Exhibition). Their push for "lights out factories" reflects the growing demand for automation and AI in alloy door and window production, positioning LEADCNC as a leader in Industry 4.0 transformation (2025: Need Auto for AI).

In conclusion, LEADCNC’s window production lines offer cutting-edge automation and precision, making them a standout choice in the aluminum window and door manufacturing industry. With over 18 years of experience, a focus on intelligent manufacturing, and trusted partnerships with top brands, LEADCNC delivers significant value to manufacturers aiming for efficiency and scalability. While their premium pricing may challenge smaller firms, the long-term advantages position them as a key player for 2025 and beyond.

Founded: 1951

Location: Karolinenstraße 1-15, 33609 Bielefeld, Germany

Overview: Schüco International is a premium name in window production line manufacturing, renowned for its high-end aluminum window equipment. Integrating sustainable technology and smart automation, Schüco’s solutions enhance production efficiency for top-tier manufacturers in 2025. Its global authority stems from decades of expertise and a robust service network.

Schüco International, a globally esteemed leader in building envelope solutions, is renowned for its advanced window production lines, particularly for aluminum and PVC-U systems. This comprehensive evaluation, conducted from a third-party perspective, assesses Schüco’s window production line offerings as of March 19, 2025, drawing on industry data, market analysis, and user feedback to provide a detailed overview of their technology, performance, and market standing.

Founded in 1951 and headquartered in Bielefeld, Germany, Schüco International has grown into a dominant force in the window production industry, specializing in system solutions for windows, doors, and façades made from aluminum, steel, and PVC-U. With a turnover of 2.11 billion euros in 2023 and a presence in over 80 countries, Schüco employs approximately 6,300 people and collaborates with 40,000 fabricators, architects, and investors worldwide (Schüco International Official Website). The company’s comprehensive approach spans the entire building project lifecycle—from design and fabrication to installation and after-sales service—supported by its production machinery and digital tools. Schüco’s window production lines, such as the AWS (Aluminium Window System) and CT 70 series, are benchmarks in the industry, known for their innovative design and sustainability focus. Their leadership is further evidenced by strategic partnerships, such as the minority investment in Skyline Windows in 2024, making Skyline the exclusive North American distributor of Schüco products, enhancing their market penetration in key regions (Schüco USA).

Schüco’s window production lines are renowned for their innovation and high performance. Key products include the AWS series, such as the AWS 50 and AWS 90.SI⁺, which are designed for excellent thermal insulation and sound reduction. The AWS 90.SI⁺ is passivhaus-certified, indicating its superior energy efficiency, making it ideal for energy-conscious projects (Windows | Schüco). Schüco windows are available in various configurations, including different basic depths, opening types, and comfort components, catering to diverse architectural needs. They also offer customization options for security, with features like additional locking points to achieve high resistance classes (e.g., RC 3), ensuring concealed and highly effective burglar protection (Windows - Schüco Singapore). Schüco provides machines for fabrication, integral to their window production lines, supporting fabricators in creating high-quality windows efficiently.

A table summarizing key features of Schüco’s window production lines is provided below:

| Feature | Details |

|---|---|

| Key Products | AWS 50, AWS 90.SI⁺, CT 70 series |

| Materials Processed | Aluminum, PVC-U, Steel |

| Company Experience | > 70 years (since 1951) |

| Energy Efficiency | Passivhaus-certified (e.g., AWS 90.SI⁺) |

| Security Features | Up to resistance class 3 (RC 3) with locking points |

| Benefits | High thermal insulation, sound reduction, customization |

| Target Users | Architects, fabricators, home owners, commercial builders |

| Additional Features | Digital tools, slim profiles, concealed fittings |

This table reflects data from Schüco’s product portfolio, emphasizing their focus on performance and versatility.

Schüco is highly regarded for its premium design and technical capabilities. Architects and designers appreciate the aesthetic appeal of Schüco windows, particularly their slim profiles and concealed fittings that allow for clean, linear designs, enhancing light and transparency (Schüco: Aluminium windows and facades | Archiproducts). Home owners value the comfort, security, and energy efficiency, with customization options like lockable handles and closing monitoring systems (Windows - Schüco Singapore). Industry experts commend Schüco’s comprehensive approach and its role in advancing sustainable building practices, with passivhaus certification enhancing its reputation for energy efficiency.

While specific pricing isn’t publicly disclosed, Schüco’s products are positioned as premium offerings due to their high quality, advanced technology, and customization options. This may make them less accessible to budget-conscious consumers or smaller projects compared to competitors like Yilmaz Machine. However, the long-term benefits, such as energy savings and enhanced security, likely justify the investment. No widespread criticisms or recalls are noted as of 2025, suggesting a strong reputation for reliability (Schüco: Archiproducts).

As of March 2025, Schüco continues to innovate, focusing on sustainability and digitalization. Their 2024 partnership with Skyline Windows in North America aims to expand market presence, with Skyline as the exclusive distributor (Schüco USA). Schüco is also advancing digital solutions like the Schüco Fabrication Data Center, aligning with trends toward smart buildings and integrated systems (Bauwerk Building Solutions). Their emphasis on energy-efficient, passivhaus-certified products meets the growing demand for green building solutions.

Schüco International’s window production lines represent the pinnacle of quality, innovation, and sustainability in the building envelope industry. With over 70 years of expertise, a robust product portfolio, and a commitment to excellence, Schüco sets benchmarks for window systems. Their premium pricing reflects their value, making them a preferred choice for architects, builders, and home owners seeking high-end, sustainable solutions in 2025. Schüco’s focus on digitalization and green technology ensures they remain a leader in the evolving industry.

Founded: 1970

Location: Via Masaccio 24, 47822 Santarcangelo di Romagna (RN), Italy

Overview: FOM Industrie, an Italian leader, excels in delivering high-precision equipment for window production lines. Its cutting machines, CNC centers, and automated assembly systems cater to aluminum and PVC manufacturers worldwide. In 2025, FOM’s modular designs and technical excellence solidify its reputation among top manufacturers.

FOM Industrie, a globally recognized leader in window production line machinery, is renowned for its advanced equipment for aluminum, PVC, and other materials used in window and door manufacturing. This comprehensive evaluation, conducted from a third-party perspective, assesses FOM Industrie’s window production line offerings as of March 19, 2025, drawing on industry data, market analysis, and user feedback to provide a detailed overview of their technology, performance, and market standing.

Founded in 1972 and headquartered in Cattolica, Italy, FOM Industrie has established itself as a leading manufacturer of machinery for the window and door industry. The company is part of the FOM Group, which comprises nine manufacturing companies, ten sales branches, and 55 official distributors worldwide, reflecting a strong global presence. With an annual turnover of approximately 45 million euros and employing about 300 people, FOM Industrie is known for its commitment to ethics, transparency, and excellence, as evidenced by its adoption of an Ethics Code under Legislative Decree No. 231 of June 8, 2001 (FOM Industrie Official Website). Their focus on R&D and the application of the latest mechanical and electronic technology has positioned them as a benchmark for customers in the window and door frames industry, with operations spanning from small workshops to large-scale manufacturing facilities.

FOM Industrie offers a comprehensive range of high-technology machine tools designed for window fabrication, including automatic cutting and machining lines, CNC machining centers, and sawing machines. Key products include the LMX 650, a fully automated line with up to 18 electrospindles and infinite 360° blade rotation, and the AXEL 5 and AXEL 4 CNC machining centers, 5-axis and 4-axis vertical milling centers for aluminum profiles (DirectIndustry - FOM Industrie). The LT3 550 and LT 65 sawing machines provide high accuracy for aluminum and PVC profiles. These machines feature up to 50 motorized CNC axes, ensuring exceptional quality and efficiency (Glassonweb.com - FOM Industrie at Veteco).

A table summarizing key features of FOM Industrie’s window production lines is provided below:

| Feature | Details |

|---|---|

| Key Products | LMX 650, AXEL 5, AXEL 4, LT3 550, LT 65 |

| Materials Processed | Aluminum, PVC, Steel |

| Company Experience | > 50 years (since 1972) |

| Automation Level | High, with up to 50 motorized CNC axes |

| Benefits | High precision, efficiency, versatility |

| Target Users | Small workshops, large-scale manufacturers |

| Additional Features | Industry 4.0 ready, digital platforms (LOLA, CARL) |

This table reflects FOM Industrie’s focus on delivering robust and adaptable solutions (FOM Industrie at WinDoor-tech).

FOM Industrie is highly regarded for its innovative technology and reliable performance. Users appreciate the precision and efficiency of their machinery, which streamlines cutting, milling, drilling, and assembly processes (Avantek Machinery - FOM Industrie). Their global network and participation in events like WinDoor-tech, showcasing the LMX 650, reinforce their leadership in production automation and digitalization (FOM Industrie at WinDoor-tech). Experts note their role as a benchmark in the industry, with applications in residential windows enhancing energy efficiency and aesthetics.

While specific pricing isn’t disclosed, FOM Industrie’s machinery is considered high-end due to its advanced technology, potentially posing a cost barrier for smaller manufacturers. However, the long-term benefits of efficiency and quality output justify the investment for larger operations (Avantek Machinery - FOM Industrie). No significant recalls or criticisms are reported as of 2025, indicating a strong performance record.

As of March 2025, FOM Industrie is advancing Industry 4.0 readiness with innovations like LOLA, a web platform for predictive maintenance and data monitoring, and CARL, an augmented reality tool for designing customized workshops (Home - FOM Industrie). Their LMX 650 line, showcased at Veteco, highlights their focus on automation (Glassonweb.com - FOM Industrie at Veteco). These align with trends toward digital transformation and sustainable manufacturing.

FOM Industrie’s window production lines combine innovation and efficiency, making them a standout in the industry. With over 50 years of experience, a global presence, and cutting-edge solutions like LOLA and CARL, they cater to diverse manufacturing needs. Their focus on Industry 4.0 ensures they remain competitive, offering exceptional value to fabricators worldwide in 2025.

Founded: 1980

Location: Taşdelen Mah. Sırrı Çelik Bulvarı No:7, Çekmeköy, Istanbul, Turkey

Overview: Yilmaz Machine, a Turkish standout, offers cost-effective window production line solutions for aluminum and PVC processing. From cutting to welding, its reliable equipment supports small-to-medium manufacturers globally. In 2025, Yilmaz’s affordability and durability make it a trusted name in emerging markets.

Yilmaz Machine, a leading Turkish manufacturer of machinery for the window and door industry, has established itself as a key player in the global market for window production lines. This report provides a detailed evaluation of Yilmaz Machine’s window production line offerings, based on industry data, market analysis, and user feedback as of March 19, 2025.

Yilmaz Machine was founded in 1977 in Turkey and has since grown into a prominent manufacturer of machinery for processing PVC and aluminum profiles, primarily for window and door production. The company operates from a state-of-the-art production facility spanning 28,000 square meters and exports its products to over 85 countries through a network of more than 65 distributors worldwide (Yilmaz Machinery - International Machinery). Yilmaz Machine is recognized for its commitment to quality, reliability, and affordability, making it a trusted partner for manufacturers globally. The company’s focus on research, development, and customer satisfaction has positioned it as a benchmark in the industry, with a strong emphasis on ethical practices, social responsibility, and technological innovation. Their participation in major industry events, such as the Eurasia Window, Door and Glass Fair, where they showcase new machine models developed with 100% Turkish engineering, highlights their contribution to local industry and global market presence (Yilmaz Machine at Eurasia Window Fair).

Yilmaz Machine offers a comprehensive range of machinery specifically designed for window production, catering to both small workshops and large-scale manufacturers. Their product portfolio includes cut-off saws, miter saws, CNC cutting centers like the NCR-300, PVC welders, and cleaners, all engineered for efficiency, precision, and versatility (Yilmaz Machine Official Website). Key features include automation with CNC control, such as the AIM series for aluminum processing and the PIM series for PVC, which reduce manual labor and increase throughput. The equipment supports processing of aluminum, PVC, and even wood profiles, expanding its applications beyond windows to furniture manufacturing. Products like the PWB 4100 2 in 1 mounting and glazing bench offer pneumatic table tilt for enhanced functionality (Used Yilmaz Machine Window for sale).

A table summarizing key features of Yilmaz Machine’s window production lines is provided below:

| Feature | Details |

|---|---|

| Key Products | Cut-off saws, miter saws, CNC cutting centers, PVC welders, cleaners |

| Materials Processed | Aluminum, PVC, Wood |

| Company Experience | > 45 years (since 1977) |

| Automation Level | High, with CNC and automated welding options |

| Benefits | Precision, efficiency, affordability |

| Target Users | Small workshops, large-scale manufacturers |

| Additional Features | Turkish engineering, global export network |

This table reflects Yilmaz Machine’s focus on cost-effective, high-performance solutions.

Yilmaz Machine is highly regarded for the functionality, reliability, and affordability of its products. Users appreciate the premium components and engineering details, which ensure consistent performance. Their participation in events like the Eurasia Window Fair showcases their latest innovations, attracting significant global attention (Yilmaz Machine at Eurasia Window Fair). Machines like the CNC 608 2-axis cleaner for PVC profiles offer flexibility with configurable parameters, enhancing user satisfaction (Used Yilmaz Machine Window for sale). Experts note their contribution to local Turkish industry with 100% domestic engineering, reinforcing their reputation as a competitive and reliable provider.

Yilmaz Machine offers high-quality machinery at competitive prices, with an aluminum profile machine line listed at $61,231.00 for a minimum order of 2 sets (Yilmaz Machine - Alibaba). This affordability makes them attractive to a wide range of manufacturers. No significant criticisms or recalls are reported as of 2025, though the initial cost might be a consideration for very small operations. The value delivered through efficiency and reliability mitigates such concerns (Yilmaz Machine - The Fabricator).

As of March 2025, Yilmaz Machine continues to innovate, showcasing new models at events like Fensterbau Frontale 2024, including the AIM 3410 and PIM 6509, which highlight their focus on automation (YILMAZ MACHINE | LinkedIn). Their digital initiatives, like the Digital Studio connection at fairs, enhance remote client engagement. This aligns with industry trends toward smart manufacturing, ensuring Yilmaz Machine meets global demands for efficiency and precision.

Yilmaz Machine stands out as a reliable and competitive provider of window production line machinery, with a strong global presence and a commitment to quality, innovation, and customer satisfaction. Their comprehensive range, including cutting machines, CNC centers, and PVC processing equipment, caters to diverse needs. Their focus on affordability and technological advancement positions them as a key player in the window manufacturing sector in 2025 and beyond.

Founded: 1970

Location: Via Archimede 10, 41019 Soliera (MO), Italy

Overview: Emmegi, part of Italy’s Voilàp Group, is a technical innovator in window production line manufacturing. Its CNC machining centers and automated systems excel in aluminum window production, offering precision and speed. In 2025, Emmegi’s global presence and cutting-edge technology cement its leadership status.

Emmegi, a leading Italian manufacturer of machinery for the window and door industry, has established itself as a global benchmark in the design, production, and sale of systems for machining aluminum, PVC, and steel profiles. This report provides a detailed evaluation of Emmegi’s window production line offerings, based on industry data, market analysis, and user feedback as of March 19, 2025.

Founded in 1970 by Giuseppe Caiumi in Limidi di Soliera, Modena, Italy, Emmegi has grown into a global leader in the fenestration sector. The company specializes in providing integrated solutions for the machining of aluminum, PVC, and steel profiles, with a strong emphasis on innovation, quality, and customer service. Emmegi’s global presence is extensive, with operations in over 50 countries and significant branches such as Emmegi USA (established in 2006) and Emmegi Deutschland (celebrating its 10th anniversary in 2017) (Emmegi Official Website - Company Background). Part of the Voilàp Group, Emmegi strengthened its market position through the 2015 acquisition of the German Elumatec Group, creating a major industry player. Known for continuous innovation and advanced logistics, Emmegi serves as a process consultancy partner, backed by UNI EN ISO certification and a robust R&D focus.

Emmegi offers a comprehensive range of machinery and systems tailored for window production lines, catering to both aluminum and PVC profiles. Key products include CNC machining centers like the QUADRA series (2-axis, 12-axis, 13-axis) and SATELLITE XLE (5-axis), cutting machines like the VEGAMATIC series and PRECISION double-head miter saws, and welding equipment like the Fusion 4H for PVC profiles (Emmegi USA Inc. - Product Information). These machines offer high precision and automation, with the Comet R4 handling bars up to 4 meters long and the PHANTOMATIC T3A integrating multiple processes. Emmegi’s Emmegisoft software enhances production efficiency, aligning with Industry 4.0 standards.

A table summarizing key features of Emmegi’s window production lines is provided below:

| Feature | Details |

|---|---|

| Key Products | QUADRA series, SATELLITE XLE, VEGAMATIC, Fusion 4H, PHANTOMATIC T3A |

| Materials Processed | Aluminum, PVC, Steel |

| Company Experience | > 50 years (since 1970) |

| Automation Level | High, with CNC and automated welding options |

| Benefits | Precision, efficiency, scalability |

| Target Users | Small workshops, large-scale manufacturers |

| Additional Features | Software integration (Emmegisoft), Industry 4.0 ready |

This table highlights Emmegi’s advanced and adaptable solutions.

Emmegi is highly regarded for its quality and innovation. FG Trading in South Africa praises Emmegi’s extensive range, from manual to CNC systems, and their local support (FG Trading Partnership with Emmegi). Unique Window Systems’ £1 million and £2.5 million investments in Emmegi’s aluminum and PVCu machinery, respectively, reflect trust in their efficiency and quality (Unique Window Systems Investment). Experts laud Emmegi’s integrated solutions and customer support, with trade show presence reinforcing their leadership.

Emmegi’s products are premium-priced, as evidenced by Unique Window Systems’ investments (£1 million for aluminum, £2.5 million for PVCu machinery), reflecting their advanced technology. This cost may challenge smaller manufacturers, though long-term benefits justify it for larger operations. No significant criticisms are reported as of 2025, with Emmegi’s support mitigating concerns about cost and operator training.

As of March 2025, Emmegi advances with the 2015 Elumatec acquisition, enhancing their global reach, and showcases innovations like the Fusion 4H and ULTRA at Fensterbau Frontale 2024 (Emmegi’s Global Presence and Innovations). New branches in Asia and software solutions via Emmegisoft align with Industry 4.0 and sustainability trends, ensuring Emmegi meets modern manufacturing demands.

Emmegi stands out as a global leader in window production line machinery, offering high-quality, precise, and innovative solutions. With over 50 years of experience and a strong global presence, Emmegi provides exceptional value. Their premium pricing is offset by efficiency and support, positioning them as a key player in the fenestration sector for 2025 and beyond.

Founded: 1946

Location: In der Höhe 15, 54486 Mülheim an der Mosel, Germany

Overview: Stürtz Maschinenbau, with over 75 years of experience, dominates PVC window production line manufacturing. Its automated welding and cleaning systems optimize workflows for manufacturers worldwide. In 2025, Stürtz’s German-engineered reliability makes it a top choice for scalable production.

Stürz Maschinebau, a leading German manufacturer of machinery for the window and door industry, has a rich history and a strong reputation for producing high-quality equipment for PVC and aluminum window production. This report provides a detailed evaluation of Stürz Maschinebau’s window production line offerings, based on industry data, market analysis, and user feedback as of March 19, 2025.

Stürz Maschinebau was founded in 1946 by Karl Stürz in Mülheim an der Mosel, Germany. Initially focusing on simple woodworking machines, the company has evolved to specialize in machinery for the production of windows and doors, particularly those made from PVC and aluminum profiles. With over 75 years of experience, Stürz Maschinebau is known for its commitment to quality, innovation, and customer service. The company’s global presence includes a network of distributors and service centers, ensuring comprehensive support for its customers worldwide (Stürz Maschinebau Official Website). Their long history is marked by a focus on technological advancement, positioning them as a trusted partner for window and door manufacturers, with operations spanning small workshops to large industrial facilities.

Stürz Maschinebau offers a comprehensive range of machinery designed for the efficient production of windows and doors. Key products include fully automated cutting lines like the Stürz Cutting Line, high-speed welding machines for PVC profiles, and corner cleaners for finishing welded corners, all engineered for high precision, automation, and energy efficiency (Stürz Maschinebau Products). These machines support high-volume production, reducing manual labor and enhancing productivity, with user-friendly interfaces and robust construction ensuring reliability and minimal downtime.

A table summarizing key features of Stürz Maschinebau’s window production lines is provided below:

| Feature | Details |

|---|---|

| Key Products | Cutting lines, welding machines, corner cleaners |

| Materials Processed | PVC, Aluminum (some machines) |

| Company Experience | > 75 years (since 1946) |

| Automation Level | High, with automated cutting and welding |

| Benefits | Precision, efficiency, reliability |

| Target Users | Window and door manufacturers |

| Additional Features | Industry 4.0 readiness, digital solutions |

This table reflects Stürz Maschinebau’s focus on advanced, efficient solutions.

Stürz Maschinebau is highly regarded for the quality and reliability of its products. Customers praise the longevity and minimal maintenance needs, with some machines operating smoothly for over a decade (Customer Testimonials). Industry experts recognize Stürz as a leader in integrated solutions, with their trade show presence and innovation reinforcing their market position. Their customer service is also a key strength, ensuring prompt support.

Stürz Maschinebau’s products are high-end, reflecting their advanced technology and quality, though specific pricing isn’t disclosed. The initial investment is significant, but long-term benefits like productivity and reliability justify it. No widespread criticisms or recalls are reported as of 2025, indicating a strong reputation.

As of March 2025, Stürz Maschinebau advances with new cutting and welding models, integrating digital solutions for Industry 4.0 readiness, such as real-time monitoring and predictive maintenance. Their focus on energy-efficient designs aligns with sustainability trends, keeping them competitive in modern manufacturing.

Stürz Maschinebau stands out as a reliable and innovative provider of window production line machinery, with over 75 years of excellence. Their high-quality, automated solutions and focus on digitalization make them a top choice for manufacturers. As the industry evolves, Stürz remains a leader, offering value in 2025 and beyond.

Founded: 1956

Location: Urbanstraße 1, 87719 Mindelheim, Germany

Overview: Urban Machinery is a German expert in automated window production lines, excelling in PVC and aluminum processing. Its advanced welding and corner-cleaning technologies boost efficiency and quality. In 2025, Urban’s decades of innovation and global support keep it among the elite manufacturers.

Urban Machinery, a leading German manufacturer of machinery for the window and door industry, has a rich history and a strong reputation for producing high-quality equipment for processing PVC and aluminum profiles. This report provides a detailed evaluation of Urban Machinery’s window production line offerings, based on industry data, market analysis, and user feedback as of March 19, 2025, offering a thorough analysis for industry professionals and manufacturers seeking reliable solutions.

Urban Machinery was founded in 1956 in Germany and has since established itself as a prominent manufacturer of machinery for window and door production, specializing in PVC and aluminum profiles. With over 60 years of experience, the company is known for its commitment to quality, innovation, and customer service. Urban Machinery maintains a global presence through its network of distributors and service partners, ensuring comprehensive support for its customers worldwide (Urban Machinery Official Website). Their long history and focus on technological advancement position them as a trusted partner for manufacturers across various scales, from small workshops to large industrial facilities, with operations spanning Europe, Asia, and the Americas.

Urban Machinery offers a comprehensive range of machinery designed for efficient window and door production. Key products include automated cutting lines like the U-Cut series, welding machines like the U-Weld series, and cleaning machines like the U-Clean series, all engineered for high precision, automation, and energy efficiency (Urban Machinery Official Website). Some models feature CNC control, reducing manual labor and enhancing productivity, making them suitable for both small workshops and large factories. Their robust construction and user-friendly interfaces ensure reliability and minimal downtime.

A table summarizing key features of Urban Machinery’s window production lines is provided below:

| Feature | Details |

|---|---|

| Key Products | Cutting lines (U-Cut series), Welding machines (U-Weld series), Cleaning machines (U-Clean series) |

| Materials Processed | PVC, Aluminum |

| Company Experience | > 60 years (since 1956) |

| Automation Level | High, with automated and CNC-controlled options |

| Benefits | Precision, efficiency, reliability |

| Target Users | Window and door manufacturers |

| Additional Features | Energy-efficient designs, digital solutions |

This table reflects Urban Machinery’s focus on advanced, efficient solutions.

Urban Machinery is highly regarded for the quality and reliability of its products. Customers praise the longevity and minimal maintenance needs, with some reporting smooth operation for many years (Customer Testimonials). Their customer service is a key strength, providing prompt support and solutions. Industry experts recognize Urban Machinery as a leader in integrated solutions, with their trade show presence and innovation reinforcing their reputation.

Urban Machinery’s products are mid to high-end, with pricing reflecting their advanced technology, though specific figures aren’t public. The initial cost may be significant, but long-term benefits like productivity and reliability justify it. No widespread criticisms or recalls are reported as of 2025, suggesting a strong performance record.

As of March 2025, Urban Machinery advances with new models featuring improved efficiency and digital solutions for Industry 4.0, such as real-time monitoring and predictive maintenance. Their energy-efficient designs align with sustainability trends, ensuring they meet modern manufacturing needs in automation and eco-friendliness.

Urban Machinery stands out as a reliable and innovative provider of window production line machinery, with over 60 years of excellence. Their high-quality, automated solutions and focus on digitalization and sustainability make them a top choice for manufacturers. They remain a leader in 2025, offering value for efficient, high-quality window production.

Founded: 1990

Location: Sanayi Sitesi 3. Cadde No:14, 06990 Sincan, Ankara, Turkey

Overview: Ozgenc Makina, a Turkish leader, provides practical window production line equipment for aluminum and PVC windows. Its affordable cutting and assembly machines cater to growing businesses. In 2025, Ozgenc’s adaptability and cost-effectiveness enhance its global competitiveness.

Ozgenc Makina, a prominent Turkish manufacturer of machinery for the window and door industry, has established a strong reputation for delivering reliable and efficient equipment for processing PVC, aluminum, and wood profiles. This report provides a detailed evaluation of Ozgenc Makina’s window production line offerings, based on industry data, technical specifications, and market insights as of March 19, 2025, offering a thorough analysis for industry professionals and manufacturers seeking advanced production solutions.

Ozgenc Makina was founded in 1970 in Turkey and has grown into a leading manufacturer of machinery for window and door production, with a focus on PVC, aluminum, and wood profiles. With over 40 years of experience, headquartered in Nilufer, Bursa, the company employs 51-200 staff and exports to 79 countries, supported by certifications like ISO 9001 and CE (Ozgenc Makina Official Website). Their emphasis on innovation and global reach positions them as a trusted partner for manufacturers, from small joinery workshops to large industrial facilities, across Europe, Asia, Africa, and beyond.

Ozgenc Makina offers a comprehensive window production line that automates the entire manufacturing process, from cutting to final assembly. Key products include the TURBOCUT 500 for cutting, TURBOWELD 400 for welding and cleaning, and SC 200 for hardware assembly, all designed for precision, speed, and versatility (Ozgenc Makina Catalogs). Featuring CNC control and high-speed spindles, these machines reduce manual intervention and boost productivity, making them ideal for diverse production scales.

A table summarizing key features of Ozgenc Makina’s window production line is provided below:

| Feature | Details |

|---|---|

| Key Products | Cutting lines (TURBOCUT 500, OMRM 113), Welding/Cleaning (TURBOWELD 400), Assembly (SC 200) |

| Materials Processed | PVC, Aluminum, Wood |

| Company Experience | > 40 years (since 1970) |

| Automation Level | High, with CNC-controlled options and integrated conveyors |

| Benefits | High speed (3000m PVC/8hrs), precision, cost-efficiency |

| Target Users | Window and door manufacturers, joinery workshops |

| Additional Features | Patent-protected designs, live monitoring cameras |

This table highlights Ozgenc Makina’s focus on advanced, versatile solutions.

Ozgenc Makina is well-regarded for the efficiency and reliability of its machinery. Users praise models like the TURBOCUT 500 for its high-speed processing (3000m of PVC in 8 hours) and ease of integration with joinery software, while the TURBOWELD 400 is noted for seamless welding and cleaning (Ozgenc Makina LinkedIn). Industry experts recognize their innovation, such as the TURBOCUT 500’s patent protection and endorsement by Turkey’s Scientific and Technological Research Council, reinforcing their standing in the market.

Ozgenc Makina’s products are positioned in the mid-to-high price range, reflecting their advanced technology and automation features, though exact pricing isn’t publicly disclosed. The investment is offset by long-term gains in productivity and reduced labor costs. Potential criticisms might include the complexity of setup for smaller workshops or reliance on trained operators for CNC systems, but no significant recalls or widespread issues are reported as of 2025.

As of March 19, 2025, Ozgenc Makina continues to innovate, with recent updates likely focusing on enhanced automation and digital integration, such as real-time monitoring via cameras in models like TURBOCUT 500. Their machinery aligns with Industry 4.0 trends, emphasizing efficiency and adaptability. The company’s global presence in 79 countries suggests ongoing efforts to meet sustainability and automation demands in modern manufacturing.

Ozgenc Makina stands out as a reliable and innovative provider of window production line machinery, backed by over 40 years of expertise. Their high-speed, automated solutions, such as the TURBOCUT 500 and TURBOWELD 400, combined with a focus on precision and global support, make them a top choice for manufacturers. As of 2025, they remain a competitive leader, delivering value through efficient, high-quality window production systems.

Founded: 1980

Location: Via Galileo Galilei 18, 41015 Nonantola (MO), Italy

Overview: Graf Synergy rounds out the list with its innovative PVC window production line solutions, featuring seamless welding technology. Based in Italy, it delivers high-quality finishes and efficient systems for premium manufacturers. In 2025, Graf’s forward-thinking approach ensures its place among industry leaders.

Graf Synergy, a leading Italian manufacturer of machinery for the window and door industry, is renowned for its innovative solutions in PVC window production. With over 30 years of experience, this report provides a detailed evaluation of Graf Synergy’s window production line offerings, based on industry data, technical specifications, and market insights as of March 19, 2025, offering a thorough analysis for industry professionals and manufacturers seeking cutting-edge production solutions.

- Company Background and Market Leadership

- Product Features and Performance

- User and Expert Perceptions

- Pricing and Potential Criticisms

- Recent Developments and Industry Trends

- Conclusion

Founded in the 1980s in Modena, Italy, Graf Synergy has evolved from an automation provider for industries like automotive and food processing into a global leader in PVC window and door machinery. Based in Nonantola, Emilia-Romagna, the company employs around 90 staff and generates approximately $5.6 million in revenue, exporting to 79 countries (Graf Synergy Official Website). Their pioneering V-Perfect technology and turnkey factory solutions have solidified their reputation as an innovative force in the market.

Graf Synergy offers a turnkey window production line that automates cutting, welding, and assembly processes for PVC windows. Key products include the Fab Cut Plasma for cutting, SL4-FF EVO-RS for welding with V-Perfect technology, and FAZ III for assembly, all designed for high efficiency, precision, and minimal labor (Graf Synergy News). These machines feature advanced CNC control and innovative technologies, making them suitable for various production scales.

A table summarizing key features of Graf Synergy’s window production line is provided below:

| Feature | Details |

|---|---|

| Key Products | Cutting (Fab Cut Plasma), Welding (SL4-FF EVO-RS), Assembly (FAZ III) |

| Materials Processed | PVC, with metal reinforcements |

| Company Experience | > 30 years (since 1980s) |

| Automation Level | High, with CNC and plasma technology |

| Benefits | Seamless welding, high speed (480 frames/8h), cost-efficiency |

| Target Users | PVC window and door manufacturers |

| Additional Features | V-Perfect technology, automatic screw management |

This table reflects Graf Synergy’s emphasis on innovative, efficient solutions.

Graf Synergy is highly regarded for its groundbreaking V-Perfect technology, with users praising the SL4-FF EVO-RS for eliminating welding seams and reducing labor costs. The FAZ III’s high-speed assembly (up to 480 frames/8h) is also noted for its efficiency (FAZ III Details). Experts highlight their leadership in automation, evidenced by their presence at trade shows like VETECO and Fenstebau Frontale, and their successful installation of Asia’s largest automated line for Jinheung Window Co. Ltd.

Graf Synergy’s products are likely in the mid-to-high price range, reflecting their advanced technology like V-Perfect and plasma cutting, though specific pricing isn’t publicly available. The investment is justified by reduced labor and cleaning costs. Potential criticisms could include the complexity of integrating such advanced systems for smaller operations, but no widespread issues or recalls are reported as of 2025.

As of March 19, 2025, Graf Synergy continues to advance its offerings, with recent updates likely enhancing automation and digital integration, such as the intuitive software in Fab Cut Plasma. Their focus on seamless welding and high-speed assembly aligns with Industry 4.0 trends, emphasizing efficiency, sustainability, and customization, as seen in their global projects like the Jinheung installation.

Graf Synergy excels as an innovative provider of PVC window production line machinery, with over 30 years of expertise. Their advanced solutions, including V-Perfect technology in the SL4-FF EVO-RS, Fab Cut Plasma, and FAZ III, deliver unmatched efficiency and quality. As of 2025, their global reach and focus on automation position them as a top choice for manufacturers seeking cost-effective, high-performance production systems.

These top 10 window production line manufacturers represent the best in expertise, innovation, and trustworthiness. With decades—or even nearly a century—of experience, companies like Elumatec and Stürtz showcase proven reliability, while emerging players like LEADCNC bring fresh, affordable solutions. Their equipment drives the production of energy-efficient windows, meeting 2025’s sustainability trends. Whether you’re upgrading a small workshop or scaling a large factory, these manufacturers offer the technology and support to succeed.

In 2025, the window production line industry thrives on the backs of these exceptional manufacturers. From Germany’s precision engineering to Turkey’s cost-effective innovations and China’s rapid advancements, this list reflects the global diversity and strength of the sector. Explore their websites for the latest updates and solutions tailored to your window manufacturing needs.

Learn how to operate a lathe with this all-in-one beginner’s guide—covering safety, tools, setup, and expert tips. Perfect for DIYers, machinists, and students! Start turning like a pro today.

Discover the top 10 aluminium doors and windows manufacturers in China for 2025, including OPPEIN, Mannlee, and Paiya. Explore their innovative aluminium solutions, from energy-efficient windows to luxury doors, backed by LEADCNC’s advanced production lines.

Discover the unbeatable power of CNC machine centers for aluminum processing. LEADCNC’s Ultra X380 & Emerald F550 deliver 0.1mm precision for doors, windows, and more. Explore types, benefits, and why we dominate!

Rising costs and delays killing your CNC door & window profits? Upgrade to a smart window production line with LEADCNC to survive 2025!