CNC machine centers are revolutionizing modern manufacturing, particularly in industries like aluminum door and window production. These advanced, computer-controlled machines offer precision, efficiency, and versatility, making them indispensable for businesses aiming to stay competitive. At LEADCNC, we specialize in CNC solutions tailored for aluminum processing. This guide explores what a CNC machine center is, its types, components, working principles, and its specific advantages in aluminum door and window manufacturing.

A CNC (Computer Numerical Control) machine center is a sophisticated piece of equipment that uses computer programming to control tools and machinery for cutting, milling, drilling, and more. Unlike traditional manual machines, CNC machine centers automate complex tasks with high precision, often achieving tolerances as tight as 0.1 mm. In aluminum processing—especially for doors, windows, and curtain walls—these machines streamline production, ensuring consistent quality and reduced waste. Whether you’re new to CNC technology or looking to upgrade your setup, understanding its capabilities is key.

CNC machine centers come in various configurations, each suited to specific tasks. Here’s an overview of the main types and their relevance to aluminum processing:

Vertical Machining Center (VMC)

With a vertically oriented spindle, VMCs are ideal for smaller workspaces and precision tasks like engraving or milling aluminum profiles. They’re widely used for door and window frame detailing.

Horizontal Machining Center (HMC)

Featuring a horizontal spindle, HMCs excel at handling heavier aluminum workpieces. They’re perfect for high-volume production runs, such as cutting large aluminum extrusions.

5-Axis Machining Center

These advanced machines move along five axes, allowing complex shapes to be machined in a single setup. For aluminum door and window production, 5-axis centers like the LEADCNC Emerald F550 offer unmatched flexibility for intricate designs.

Aluminum-Specific Machining Centers

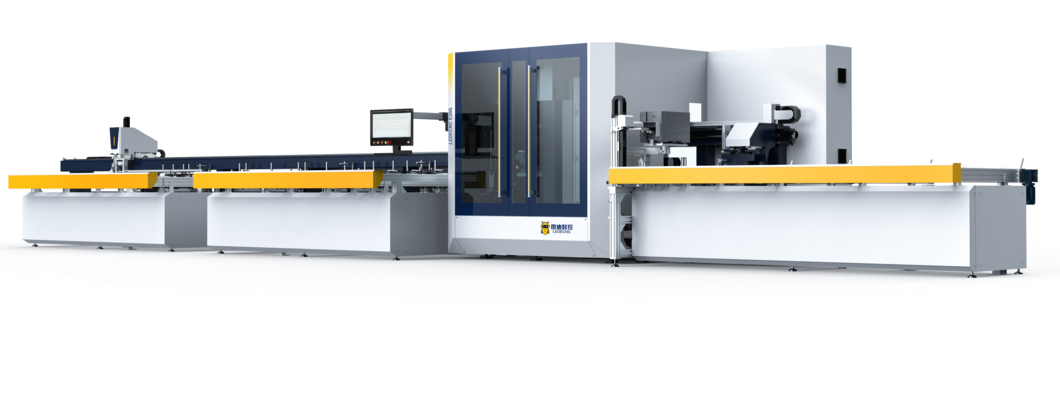

At LEADCNC, machines like the Ultra X380 are designed specifically for aluminum processing. With features like high-speed spindles and laser cutting, they’re optimized for large aluminum profiles used in windows and doors.

A CNC machine center is a synergy of advanced components working together. Here’s what makes it tick:

Spindle

The spindle rotates the cutting tool and can be vertical or horizontal. In aluminum processing, high-speed spindles ensure clean cuts and smooth finishes.

Automatic Tool Changer (ATC)

The ATC swaps tools quickly, reducing downtime. For example, switching from a milling tool to a drill bit is seamless, boosting efficiency in door and window production.

Control System

The brain of the machine, this system interprets CAD/CAM programs to guide movements. LEADCNC machines use intuitive controls for precise aluminum machining.

Workpiece Holding Device

Clamps or vises secure aluminum profiles during machining, ensuring stability and accuracy down to 0.1 mm.

The operation of a CNC machine center follows a clear process:

Programming

Designs are created in CAD software and converted into machine instructions via CAM software. For aluminum doors, this might include cutting patterns or hole placements.

Execution

The machine reads the program and moves the spindle and tools along the X, Y, and Z axes (or more in 5-axis models) to shape the aluminum.

Automation

Features like the ATC and pallet changers minimize manual intervention, making production faster and more reliable.

CNC machine centers shine in aluminum processing, especially for doors and windows. Here’s how:

Operations

They perform milling, drilling, cutting, and even laser processing on aluminum profiles. For instance, the LEADCNC Ultra X380 handles large extrusions with ease.

Advantages

Precision: Tolerances as tight as 0.1 mm ensure perfect fits for window frames.

Efficiency: Automation reduces production time.

Complexity: 5-axis machines like the Emerald F550 craft intricate designs effortlessly.

Real-World Example

The Emerald F550, with its 5-axis capability, is ideal for high-precision milling of aluminum window frames, while the Ultra X380 excels at cutting and shaping large door profiles.

Investing in a CNC machine center offers clear advantages for aluminum processing:

Productivity

Automation and multi-tasking capabilities speed up production cycles, critical for meeting tight deadlines in door and window manufacturing.

Precision

Consistent accuracy reduces material waste and ensures every piece meets specifications.

Versatility

From simple cuts to complex 3D shapes, these machines adapt to diverse aluminum processing needs.

Selecting the best machine depends on your needs:

Workpiece Size

Larger aluminum profiles (e.g., for sliding doors) require machines like the Ultra X380.

Precision Requirements

For tight tolerances, opt for a 5-axis model like the Emerald F550.

Budget

LEADCNC offers a range of options, from cost-effective 3-axis machines to advanced 5-axis solutions.

Explore our CNC Machining Centers to find the perfect fit for your aluminum processing projects.

Designed for high-precision milling, drilling, tapping, and grooving of aluminum and light alloy profiles, the Emerald F260 features a robust gantry structure, advanced automation, and seamless software integration.

This machining center offers user-friendly operation, high-speed precision, and seamless integration with ERP systems for streamlined processing of aluminum and light alloy profiles.

Designed for high-precision milling, cutting, and machining of aluminum and light alloy profiles, the Emerald F550 features a robust gantry structure, advanced automation, and seamless software integration.

CNC machine centers are the backbone of modern aluminum processing, delivering precision, efficiency, and flexibility. For door and window manufacturers, they’re a game-changer, enabling high-quality production with minimal waste. At LEADCNC, we’re proud to offer cutting-edge solutions like the Ultra X380 and Emerald F550, tailored for aluminum applications. Ready to elevate your production? Contact us today to learn more about our CNC machine centers and how they can transform your business.

Learn how to operate a lathe with this all-in-one beginner’s guide—covering safety, tools, setup, and expert tips. Perfect for DIYers, machinists, and students! Start turning like a pro today.

Discover the top 10 aluminium doors and windows manufacturers in China for 2025, including OPPEIN, Mannlee, and Paiya. Explore their innovative aluminium solutions, from energy-efficient windows to luxury doors, backed by LEADCNC’s advanced production lines.

Discover the unbeatable power of CNC machine centers for aluminum processing. LEADCNC’s Ultra X380 & Emerald F550 deliver 0.1mm precision for doors, windows, and more. Explore types, benefits, and why we dominate!

Rising costs and delays killing your CNC door & window profits? Upgrade to a smart window production line with LEADCNC to survive 2025!